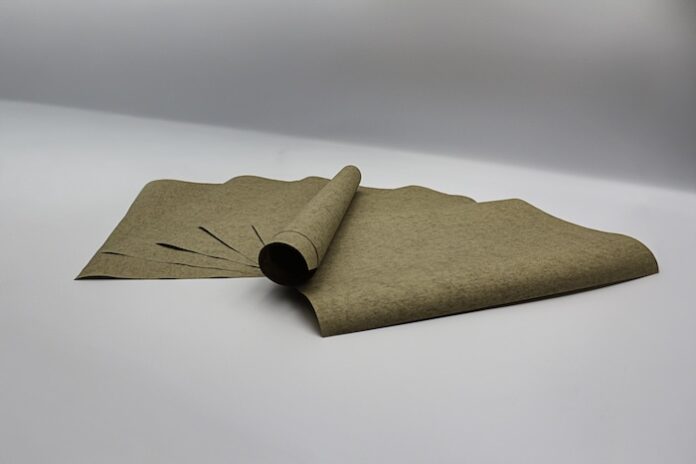

Cortec’s barrier paper portfolio just got more sustainable. Industries looking for environmentally responsible options in the area of barrier packaging should take a closer look at the new EcoBio Barrier Paper, a premium recyclable, repulpable, biodegradable barrier paper designed with the “circular economy” in mind.

EcoBio Barrier Paper starts the product life cycle as 100% recycled paper stock coated with a biobased (90-100% renewable organic carbon per ASTM D6866) and biodegradable (per OECD 301) barrier coating. In contrast to traditional barrier packaging that relies on polyethylene or foil to create a barrier, EcoBio Barrier Paper has no intentionally added plastics (or PFAS or fluorochemicals) to hinder recycling or biodegradation.

Similar to EcoShield Recyclable Barrier Paper, EcoBio Barrer Paper can be recycled through normal paper recycling streams instead of ending up in the landfill. However, EcoBio Barrier Paper goes a step further with its biodegradable, biobased coating that has the potential to open even more sustainable end of life options depending on local regulations. Most importantly, EcoBio Barrier Paper tackles moisture and grease resistance without the risk of plastic or foil pollution.

Who needs barrier packaging?

EcoBio Barrier Paper and Linerboard can be used in a variety of short-term packaging applications where moisture or grease is a concern. The barrier serves several purposes: Discourage moisture from entering or exiting the package; Avoid grease or oil seepage; and Maintain packaging integrity in the presence of moisture or grease.

Wrapping items in EcoBio Barrier Paper can help keep them dry as shipments pass through unpredictable environments with fluctuating humidity and weather patterns. Similarly, EcoBio Barrier Paper (also available as linerboard) can be used to line wooden crates or cardboard boxes (which have a tendency to absorb moisture), thus keeping goods out of direct contact with the potentially damp walls of the package.

Conversely, EcoBio Barrier Paper can be used to keep moisture or grease from leaching out of the package when, for example, metal auto parts are lightly coated with oils that could soak through and break normal paper.

As the world of sustainable packaging solutions continues to expand, Cortec remains a leader in developing industrial packaging options that address the beginning and end of the life cycle.