Prompt, an Ahmedabad-based organization with a strong legacy in the dairy sector, showcased its growing capabilities in weighing and automation solutions at Indusfood Manufacturing in Delhi. Talking to Packaging South Asia, Rohit Kalra, vice-president of sales, introduced Prompt as a company operating across multiple divisions, with dairy being its core and most established portfolio. Recognizing the limitations of relying on a single sector, Prompt has decided to diversify.

India’s dairy industry, despite being one of the largest, is largely unorganized. “Only about 30% of India’s dairy sector is organized. Amul is the biggest name. A major chunk, however, is still unorganized,” Kalra noted. This prompted Prompt to look beyond dairy and enter the industrial and manufacturing space, starting with weighing solutions and gradually moving towards automation.

At Indusfood Manufacturing, Prompt highlighted its weighing and automation division, which serves the food, beverage, dairy, and other industries. The focus was on solutions that help manufacturers ensure accuracy, improve productivity, and reduce material wastage.

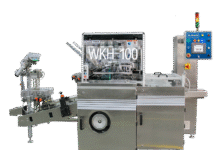

Among the key products showcased were checkweighers, bagging machines, and filling solutions. Explaining the relevance of checkweighers, Kalra said, “Take the simple example of a chip packet. If the pack says 100 grams, the manufacturer wants to ensure it is exactly 100 grams, not less, not more. Checkweighers help maintain that accuracy while avoiding wastage.”

Bagging machines and filling systems were part of the display, addressing common packaging applications such as snacks, detergents, and other consumer goods. Prompt showcased combination machines that integrate checkweighers with metal detectors, offering enhanced quality control and food safety. While X-ray inspection systems are not yet part of the portfolio, Kalra confirmed that development work is underway.

A key theme of the discussion was the company’s approach to encouraging manufacturers to move from manual or semi-automatic operations to automated systems. Kalra acknowledged that many companies remain hesitant due to perceived high investment. “What usually stops them is the fear of investment,” he said. “But once they understand productivity gains and return on investment, the mindset changes.”

According to Kalra, Prompt’s automation solutions typically deliver ROI within four to six months. “Even if a manufacturer spends ₹10 lakh, ₹20 lakh, or ₹30 lakh, depending on capacity, the ROI generally comes in four to six months. Customers who understand this are more open to shifting from manual to semi-automatic or fully automated processes,” he added.

Looking ahead, Kalra expressed keen interest in how Industry 4.0 is influencing Indian manufacturing. “We want to understand how manufacturers are looking at automation today and how ready they are for the next level,” he said, adding exhibitions such as Indusfood Manufacturing offer valuable insights into market sentiment and buyer expectations.

Prompt’s future roadmap includes extending its capabilities beyond weighing into packaging solutions. Upcoming developments include fast filling machines (FFM), bottle filling, and bottle packaging systems. “We started with weighing scales, then moved into automation. Now, the next step is to extend our product range into packaging,” Kalra explained.