The packaging industry is presently experiencing significant growth and transformation. With intense competition and a continuous influx of new products catering to consumer demands, the market is vibrant. To sustain this upward momentum, both machine builders and end users are avidly seeking to implement various new technology solutions to optimize their processes, improve product quality, and enhance the efficiency of the entire value chain.

Amid this progress, some challenges still remain to be tackled to become more efficient and sustainable. Some of the pressing problems in the packaging sector are the rising cost of packaging raw materials, maintaining the latest quality standards and the fast adoption of available technology. In such a landscape, a strong and reliable technology partner can provide that edge. Collaborating with such a partner can empower businesses to implement solutions that not only boost machine capabilities in terms of speed and performance but also align with consumer preferences and needs.

The growing opportunities for vision systems

The supermarket shelves are filled with an abundance of products that catch the interest of consumers. Here, packaging and design play a key role in grabbing the attention of consumers and convincing them to make a purchasing decision. But ever wondered how these products reach this stage? All the products have to go through a series of processes and stringent checks at the production line. Let’s take the example of the FMCG sector, whose products run to the shelves in no time to capture market share.

For this, machine builders and companies implement advanced technologies that help them to produce products without any defects and with proper packaging as per consumer requirements. Whether it’s a sleek bottle, a handy tube, or a convenient tub – all products go through checks such as precise filling level, correct labeling, and the right product code markings.

In this scenario, the vision system plays a very important part in monitoring these details during the packaging process. All this is done in the blink of an eye, at full production speed. Any defective product is discarded without stopping the production line so only the right product finds the perfect place on the market shelves. The vision system also helps to monitor the wastage of packaging material and track the products during the entire manufacturing cycle.

The features of the currently available vision system do not stop here. There are several other features such as QR scanning, 3D shape detection, OCR, and many more. All this provides growing opportunities for the implementation of the vision system in the machines and production line. This will help manufacturers to enhance their production performance and to delight consumers with packaged products of good quality.

No limits with multifunctional vision sensor

When it comes to monitoring different applications, as a machine builder you might have to juggle through sensors for different functions. The shifting consumer trends and the requirement for faster time to market pose a challenge to product manufacturing companies. They have to rely on different sensors, which increases their production cost and slows down the production process because of different response times.

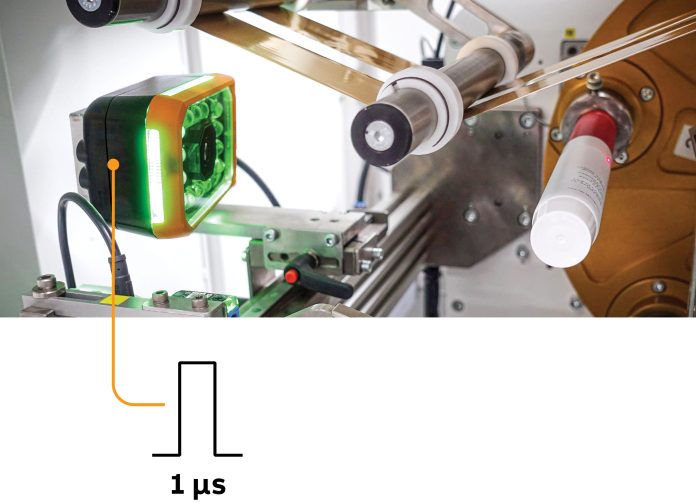

To overcome this hurdle and make the most out of this opportunity, B&R with its Integrated Machine Vision System approach has introduced a multifunctional vision sensor. Unlike many other devices in its class, there is no need to install different sensors for different functions. Instead, users simply configure the Smart Sensor in the Automation Studio engineering tool, where they can choose from a large selection of functions. This helps them to have countless features in one vision sensor. Identical hardware can be used for different applications without extra effort.

The multifunctional sensor is able to store and execute up to 255 models. As per the application requirements, additional models can easily be exchanged in the software. Furthermore, filters are included for improved image quality. These filters are a simple and inexpensive way to further improve the quality of captured images. A polarizing filter helps to eliminate reflections and glare and a collimating filter ensures optimum contrast, which helps to capture perfect images of challenging surfaces such as metals and reflective surfaces. This creates an edge for machine builders and manufacturing companies to work with no limits when it comes to a powerful vision system and maximize their performance, improve quality, and reduce their wastage.