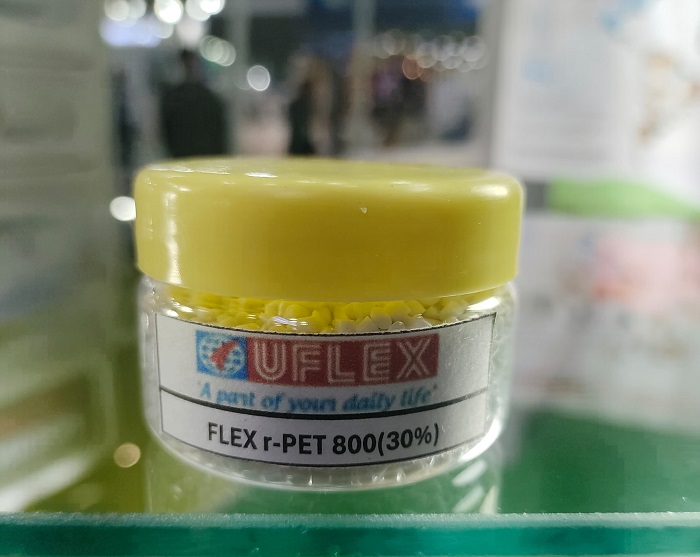

At the second Global Conclave on Plastics Recycling and Sustainability (GCPRS) held in Delhi in June 2025, the UFlex Packaging Films business showcased its single-pellet solution, which integrates 30% or more recycled PET (rPET) with virgin PET (vPET) to produce food-grade packaging.

Ashish Saxena, joint president of Packaging Films, UFlex, told Packaging South Asia that the solution enables a seamless transition from virgin PET to rPET as mandated by the EPR (Extended Producer Responsibility) rules on plastic packaging.

“The performance of our single-pellet rPET + vPET solution is nearly as good as virgin PET in terms of bottle appearance, acetaldehyde levels, and machine productivity. The single pellet makes the transition to rPET blow molding much smoother and trouble-free for our customers compared to current alternatives.”

Conventionally, recycled PET is considered inferior to virgin PET in three key areas: bottle appearance, purity, and degradation in mechanical and thermal properties. “In terms of purity, the single-pellet solution is completely free of any black specks. In terms of L and B values — where ‘L’ represents the white-grey color axis and ‘B’ represents the yellow-blue color axis — the single-pellet rPET solution is superior to conventional rPET, and its bottle appearance is virtually indistinguishable from virgin resin,” Saxena said.

The single-pellet rPET is, therefore, an excellent solution for blow-molded products such as water, cosmetics, alcoholic beverages, and edible oil, where bottle appearance plays a very important role, and users want to see the contents of the bottle with full transparency, he added. The mechanical and thermal properties of the resin — such as acetaldehyde levels and IV (intrinsic viscosity) degradation after bottle forming — are also significantly better in the single-pellet solution, according to him.

UFlex has already begun commercial-scale manufacturing of the single-pellet solution, and several customers have successfully validated the resin. Saxena acknowledged that some hesitation still exists among brand owners about how widely the EPR mandate on recycled plastic content will be enforced.

rPET for flexible packaging

To meet the mandate for recycled content in flexible packaging, solutions are needed for all three major polymers used in its production — polyethylene terephthalate (PET), polypropylene (PP), and polyethylene (PE). He added, “UFlex is the only company in India — and perhaps the world with a food contact-safe (FDA-approved) solution for all three resins.

“Our food-safe PCR PET is already available as an FSSAI and FDA-approved BOPET film and is being used by customers in India and abroad. Our food-safe PE and PP solutions are FDA-approved, and FSSAI approval is currently under process.”

On participating in the conclave, Saxena said, “We are a leader in the sustainability and recycling space. UFlex was the first company in the world to earn recognition at the Davos Recycle Forum in 1995 for conceptualizing the recycling of mixed plastic waste. Even today, we lead from the front with our solutions in PET, PP, and PE.”

UFlex has a global network of recycling facilities in Egypt, Poland, and Mexico, in addition to India. The Malanpur facility in Madhya Pradesh, India, recycles waste from aseptic packaging cartons that are delaminated and repurposed—another industry-first, Saxena said.

“Sustainability is critical to the packaging industry’s growth and survival. At UFlex, we define ‘sustainability’ through the lens of our customers and our country. What works for another country may not necessarily work for us here in India. Hence, our solutions are rooted in the realities, challenges, and opportunities of India,” Saxena said.

For instance, UFlex has developed a food-grade PE solution based on milk pouches. In India, we don’t consume milk in HDPE containers as is common in Europe. For us, the right recycling format was to take these milk pouches and convert them into usable resin.