Heidelberg says it made a strong impact at China Print 2025 in Beijing from 15 to 19 May, where customers from the packaging sector in particular invested in its sheetfed technology. A total of just under 350 printing units were sold, which exceeded the company’s expectations.

“The huge interest in the innovations and displays at our stand provides impressive proof that Heidelberg is a leading market player in China,” says David Schmedding, chief technology & sales officer at Heidelberg. “We won over a large number of customers with our integrated solutions for packaging and commercial printing from a single source, many of which are manufactured locally. The resulting incoming orders have given us a strong start to the new financial year, which began in April.”

Staged every four years, the event is China’s largest trade show for the printing industry. This year, it drew some 120,000 visitors, including a large number from all over Asia and beyond, with Heidelberg recording the highest visitor numbers. In addition to the visitors flocking to the company’s stand, around 1.3 million people are said to have tuned in online to watch its live presentations.

“Packaging printing is proving to be a growth driver for our business in China, too,” states Jürgen Otto, CEO of Heidelberg. “This development reaffirms our growth strategy – the continuous and targeted expansion of our portfolio as a systems integrator for this key market segment. The company is also benefiting from its comprehensive sales and service network and its local production operations, which largely cover demand in China.”

Packaging printing drives growth

An annual increase of around 4% in paper-based packaging makes the Chinese packaging market a growth driver for Heidelberg. Packaging and labels already account for almost 50% of the Chinese printing industry, and this share is continuing to grow – a development that is emphasized by the numerous deals struck at China print.

A leading packaging printer in northern China placed an order with Heidelberg for two Speedmaster XL 106 Peak Performance presses, representing a total of 13 printing units.

A packaging manufacturer in eastern China invested in two Speedmaster XL 75 presses, corresponding to a total of 19 printing units, to complement its 2024 investment in a Speedmaster XL 106 and a Speedmaster XL 75 with FoilStar technology.

Heidelberg got an order from a packaging customer in southern China for two long Speedmaster CX 104 presses with UV technology. Founded as recently as 2016, this company chose the Speedmaster CX 104, which Heidelberg manufactures locally in China, for quality, efficiency, and productivity. The customer is looking to use the new UV presses to expand its business from standard packaging to include high-end solutions for products such as spirits and cosmetics.

Jetfire 50 digital system celebrates trade show debut in Asia

Just as in other countries, digital printing is also becoming increasingly important in China, which is why the debut presentation of the Jetfire 50 from Heidelberg at an Asian trade show proved to be a particular highlight for many visitors. Heidelberg showcased the industrial inkjet printing press alongside a complete digital ecosystem consisting of machinery, software, consumables, service, and consulting. Using the new Prinect Touch Free software, the system can be integrated into a hybrid production environment with offset printing. Assisted by artificial intelligence, the software determines the most efficient and cost-effective means of production.

Shengda Printing Technology, which is China’s largest web-to-print company, keeps on growing, and generates annual sales totaling some 375 million Euros, is the first Chinese user of a Jetfire 50. The company is continuously forging ahead with its digital transformation and increasingly focusing on digital printing.

“The Chinese market is driving innovation in the printing sector and China Print has shown that this country’s printing industry is also following global trends, investing more and more in highly automated, efficient, and fully integrated solutions. Added to that is rising demand from end customers for more sustainable, paper-based packaging. All this makes the digitalized solutions from Heidelberg especially attractive for this important market,” sums up Otto.

Centered on digitalization

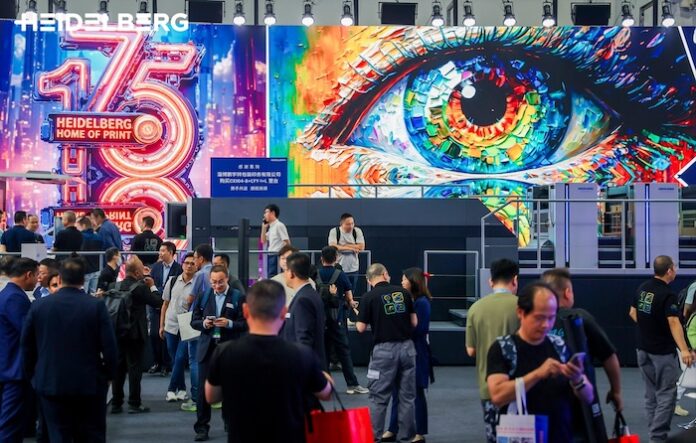

Showcased on a footprint of over 2,000 square meters, the company’s packaging and commercial printing solutions focused on enhanced efficiency and productivity, end-to-end hybrid production using offset and digital printing and Prinect Touch Free control, the development of new business opportunities, and the digital transformation of the sector.

Heidelberg stood out at the trade show thanks to its interactive customer journey comprising over 100 digital touchpoints, the Digitalization Experience Center, and a comprehensive application gallery with almost 100 print products that demonstrated the options print shops can offer their customers.