Mumbai-based ACG covers a large part of the pharma packaging supply chain from films, foils, tablet pressing, coating and blister packing and cartoning machines to inspection and track & trace technology. The global company dominates the Indian market and has been especially active in the US market over the past two years. At interpack, ACG presented its integrated pharma manufacturing solutions including its QuestTM FB ll, which it calls a next generation lab unit for granulation and Wurster coating, and the ProtabTM 300 single rotary tablet press aimed at small- and medium-scale batch production. Also shown at its stand was the AF 90T capsule-filling machine along with the Accura 100 FF automatic capsule check-weigher. The BMAX-Vektor integrated blister packing and cartoning line was also shown at interpack.

At its stand, ACG announced its acquisition of Croatian specialized software company IN2trace for an undisclosed sum. ACG Inspection Systems’ chief executive officer Ettore Cucchetti, who is based in Mumbai, said, “Acquiring IN2trace is another key step towards consolidation of our global footprint in the tract and trace business, It creates a strong manufacturing, support and development base for ACG inspection in Europe, increases our serialization expertise and expands our enterprise-level product portfolio. We see this acquisition as a key driver for the adoption of advanced serialization technology by pharmaceutical manufacturers.”

cartoning line with inline tamperevident labelling, inspection and the printing of track & trace data

generated by the newly acquired IN2trace software systems

ACG was keen to highlight its serialization and track & trace solutions that can help pharmaceutical companies meet global serialization demands. The innovative machine vision systems of ACG are designed to inspect quality while helping maintain traceability. In this context, Cucchetti spoke about the challenges that the pharma industry faces both within India and for its growing exports. He said that the shifting of the Indian government’s policy concerning non-branded generics was increasing the price pressure on manufacturers, which in fact meant that improvisations are needed in machines and processes to improve process efficiency. Globally, the challenge is for increasingly better defined tract & trace ecosystems.

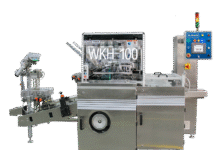

Cucchetti said that ACG was well placed for the coming scenario in terms of both efficiencies and the track & trace compliance legislation that is coming globally, “We understand the factors that control the things that interact together in the pharma supply process. We also make the capsules, which means we can contribute to better quality and better costs and add value to the product.” He demonstrated the BMAX-Vektor blister packing and cartoning line with inline tamper-evident labelling, inspection and the printing of track & trace data generated by the newly acquired IN2trace software systems.

ACG’s strategy is to help its customers grow their business while meeting the impending global regulatory compliances for pharma packaging. “Everyone has to be equipped, genuine and alert,” said Cucchetti. According to him, Turkey has already adopted the new track & trace regulations that require unique serial numbers that are random on every pack; the FDA is second and Europe will implement will enact the compliance in 2018. Packaging runs will have to serialized and disaggregated for distribution while the serialization data will have to be maintained for protection of the value chain and the brand. Secure data warehousing will be compulsory for 7 years. Adding to the complexity of the challenges ahead is that each country uses the 14-digit code differently.

ACG’s strategy is to help its customers grow their business while meeting the impending global regulatory compliances for pharma packaging. “Everyone has to be equipped, genuine and alert,” said Cucchetti. According to him, Turkey has already adopted the new track & trace regulations that require unique serial numbers that are random on every pack; the FDA is second and Europe will implement will enact the compliance in 2018. Packaging runs will have to serialized and disaggregated for distribution while the serialization data will have to be maintained for protection of the value chain and the brand. Secure data warehousing will be compulsory for 7 years. Adding to the complexity of the challenges ahead is that each country uses the 14-digit code differently.