When a book of paper samples arrives in the post, the recipient is often most interested in the samples themselves. Iggesund Paperboard has come up with its new swatch book of Invercote G, Invercote Creato and Invercote Duo. “Invercote has a dimensional stability and flexibility which makes it a good choice for people who want to use embossing to give their brochure or other printed material a third dimension,” explains Alex Guglielmi, one of Iggesund’s market technicians. He supervised the book’s production with a special focus on the embossing. “It can heighten the tactile experience, attract more attention and, not least, reinforce the experience of quality.”

Good tools are needed to achieve good-quality embossing. For this production Iggesund worked with the Swiss toolmaker SMR Stanztechnik. “In the swatch book our main task was to emboss the details in the photos,” Guglielmi says. “In doing so, it’s important not to change or distort the basic concept of the image.”

One example is the large embossing of an island on the cover. The embossing runs across the front cover, spine and back cover. The first test embossing of the image made a stone, which had been in the background, appear to have moved closer to the viewer. “We had to remake the tool to avoid creating this effect and now we’ve achieved the right balance between the image and the embossing,” he says. In another photo the embossing of an eye had to be redone. The effect was not clear enough so the tool had to be adjusted to create a more obvious visual impression. Another effect Guglielmi likes to mention is how the printing and embossing of the name Invercote work together on the first page of the sample book.

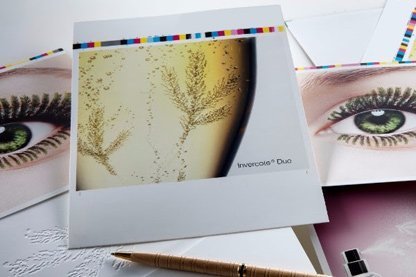

Invercote Duo is a very good material for exploring the limits of embossing. Finishing it with special varnishes highlights the embossing and champagne bubbles to produce this very sophisticated end result. © Iggesund

“It’s really easy to go wrong doing this. I usually recommend that people really think about and understand what they are going to highlight with embossing and printing. As it is a symbiosis between the paperboard, embossing tools and printing, it’s far easier to detect the smallest mis-register when you emboss along straight lines. Often output and quality are misunderstood. So when you have these demanding elements coming together, I often recommend reducing the number of single positions in a sheet to achieve the best registration between printed and embossed images.”

When a project calls for finishing processes that require multiple press passes, Invercote’s dimensional stability provides exceptional registration. Normally, printers find themselves trying to convince their clients to limit the number of press passes in order to avoid registration issues. But Invercote’s dimensional stability allows you to take on challenges. To demonstrate Invercote’s performance in this area, Iggesund has produced printed projects with more than 20 press passes with good results.

Packaging South Asia is the cooperating media partner for drupa 2016 which is scheduled to be held from 31 May to 10 June at Dusseldorf, Germany.