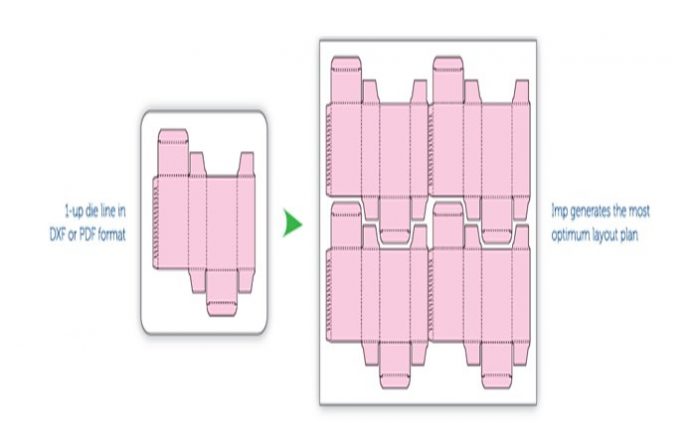

The process of creating cost-effective, print-ready layouts is made simpler with automation by Imp, an intelligent software that has key innovations and algorithms built into it. The software can effectively automate ganging and imposition of layout creation for books and diecut jobs on both sheetfed and webfed presses. What really sets the Imp software apart is its ability to calculate optimum print and die layouts for jobs of any size, quantity and color, thereby making it a tool of choice for estimators who have used it once. They can easily and effectively evaluate the optimum layout for a job and minimize printing and fi nishing costs. The makers of the software, InSoft Automation, have always maintained that they add features to it on the basis of feedback from their customers.

InSoft Automation insists that Imp is a one-of-a-kind layout planning software for digital and offset printing. The software has won the most prestigious of printing technology awards—the Intertech Technology Award 2016—given by Printing Industries of America (PIA). From the user’s point of view, the efficacy of this product is best explained by its ability to increase the profi t margin. The tool configures cost and technical parameters of multiple printers simultaneously, which spares the printer a major headache especially when he unsure whether to opt for digital or offset printing for specific jobs.

Imp software allows printers very good economies of scale and they can process more jobs in less time and with less manpower. The print layout creation (either in prepress, planning or estimation stages) is optimized for speed and efficiency by a few factors, signifi cantly boosting prepress throughput of print layouts. A client of InSoft and a user of the Imp software, Andrey Gruzin of INT Publishing says, “The main benefit of using Imp in our company is optimization of workflow in prepress department. It allows us to increase the volume of jobs two times without increasing the number of employees. The other valuable benefit of Imp software is decrease in the cost of producing jobs (about 22% is the average reduction of material costs during the last year).”

The Imp software is designed to achieve effi ciency through accurate and speedier delivery and consistent prevention of error that manual processes are prone to. It is not difficult to see why this tool has been so successful, especially with the kind of operational flow it offers. Broadly, the four easy steps to layout planning are automatic selection of the right signatures; automatic creation of the correct assembly; automatic selection of optimum sheet or reel; and automatic selection of the correct press. The three easy steps to printing are job intent (XML, CSV or PDF); selection of paper grade and inks; and selection of binding method combining to make print-ready layouts.

InSoft’s ganging software can help optimize jobs with varied quantities, colors and coatings across multiple sheets, sizes and presses. The ganging tool offers printers the option to pool the entire day’s jobs together, set the priorities and then hit a button to automatically generate efficient ganged layouts. The software ensures the same level of ease while creating layouts for packaging cartons, labels, flyers, folded leaflets, books or magazines seamlessly; the software also allows cross-ganging of different jobs. Further optimization is possible with semi-automatic tools that allow a ganging operator to optimize further depending upon job priorities.