Silver has been known to be antimicrobial since antiquity when water was stored in silver jugs to kill bacteria. More recently, silver nanoparticles are used in clothing to prevent socks and teeshirts getting stinky. Adding them to cardstock, as Theresa Dankovich, post doctoral associate at Carnegie Mellon University in the US has done, creates an antimicro- bial paper that is an effective water purifier. Her invention has already been field trialled and will be distributed to people in Haiti, Kenya, India, and Ghana. It is hoped that the Drinkable Book will help reduce the number of people dying from diseases associated with contaminated water such as cholera, typhoid and dysentery, estimated at 3.4 million.

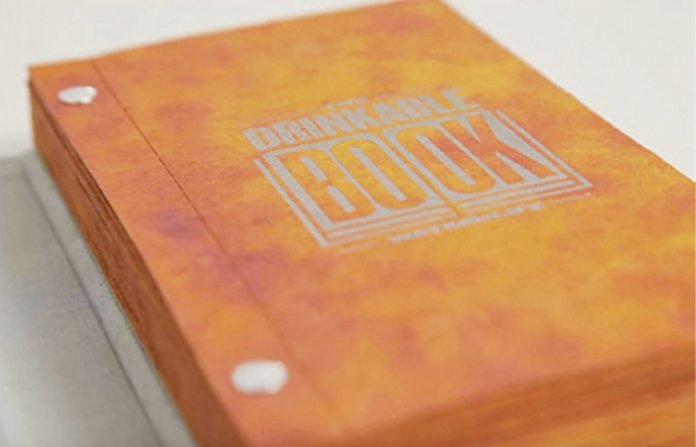

The Drinkable Book has 24 pages, each split by perforation into two squares good for treating up to 100 litres of water. The antimicrobial pages are bound into a book roughly the size of a hardback novel and packaged in a slipcase. This slipcase is also the filter box. Sheets are torn from the book, inserted into the filter box and water poured onto the sheet. As water flows through, the silver nanoparticles poison bacteria in the water. The result is water with 99.9% less bacteria, rendering it potable. The Drinkable Book pages cost around 10 US cents each and each half page can last up to a month. One book can provide water filtration for up to four years, making it good for 5,000 litres of clean water.

Pages are about 0.5 mm thick and printed with pictogram instructions for use, plus hygiene and water safety tips in English and local languages. The drinkable books produced so far are letterpress printed with specially created food grade inks in an initial run of 1,000. To get this product to market, Dankovich is working with DBB New York, an ad agency and Water is Life, a non-profit organization that develops clean water technologies. Water is Life supports over one billion people worldwide surviving on barely a quarter of a litre of clean water a day.

Expectations are that the book will be available this year, but that may be a little ambitious. The most difficult problem is to scale up production of the impregnated pages and of the printing. The letterpress method was selected because it “was the best option that allowed us the level of control that we needed,” according to Brian Gartside, designer at DDB New York. If this technology is to be effective the group must work out how to produce tens of thousands of Drinkable Books, taking into account cleanliness in production, suitability of the inks and stock for the print process, ink and substrate costs, and of course distribution and on going support for Drinkable Book users. Can used pages be recycled? Are refills for the slipcase/filter box available? How can results be monitored?

Despite these and other challenges to implementing this project, it’s extremely exciting with profound implications for developing countries. Although the silver nano particles won’t solve problem of organic pollutants and heavy metals, the Drinkable Book sets an innovative precedent for water purification technology. And it’s a great example of how books can keep evolving for all sorts of unexpected uses.