Today, the converting industry is facing many challenges. One of them is the increasing cost of raw materials and consumables. While new technologies are being adopted to increase productivity, there is still a need to address the energy (electrical and thermal) and consumable costs required for the process. This energy is used in the drying process where the wet film is dried and solvents are evaporated and exhausted. Post drying, the hot solvent laden air which is exhausted to the atmosphere from the dryer still contains around 50% of the thermal energy fed to it. Hence, there is a great potential to recover the energy being exhausted to the atmosphere after the drying process.

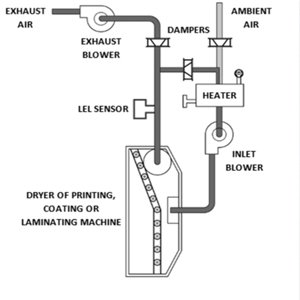

One way of achieving recovery of energy is by partly recirculating the hot solvent laden air exhausted from the dryer back into the process. During this process, for safety reasons, the concentrations of solvents in the air are required to be kept below 25% of the Lower Explosive Limit (LEL) value of the solvent. An increase in the solvent concentration above the LEL invites a risk of explosion that could be dangerous to human life as well as capital machinery.

Continuous LEL monitoring and control is necessary to avoid the dangerous effects ofhigher concentration of solvents in the air. The LEL monitoring solution from ATE and New Instruments and Research for Analysis (NIRA)is an analytical system that analyzes the concentration of solvents (in g/m3 and % LEL) in the air. A part of the hot air leaving as exhaust can be automatically recirculated back into the inlet air channel, provided the solvent concentration in the exhaust air measures below 25% of the LEL value. This is done by the use of automated dampers which get appropriate inputs of the solvent concentration through the controller. This is a safe method of recycling solvent laden air.