In the film and packaging sector, the circular economy has been an increasingly important topic for several years now. This sector is experiencing a radical change that presents new challenges, also for quality assurance systems. BST eltromat, a globally leading manufacturer of these systems, says it is at the forefront of helping to shape the transformation process toward a circular economy.

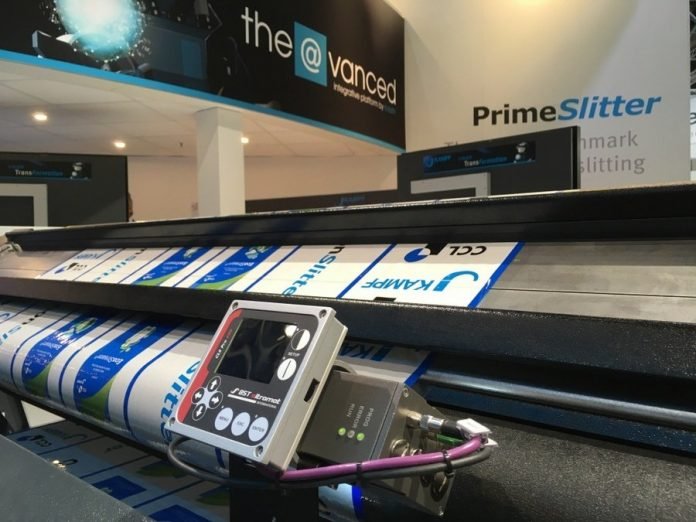

Web guiding, register control, web monitoring, 100% inspection, and color measurement – quality assurance systems are minimizing material and energy consumption as well as waste, particularly in the manufacture of flexible packaging, the company says. The systems are simple and safe to operate and they shorten the setup processes and guarantee a constant level of production quality.

And, for the purposes of Industry 4.0, they allow for cross-process integration with upstream and downstream production steps. Manufacturers thus enable different areas to share process data between their machines and solutions. This integration opens up additional, previously unknown options for increasing efficiency in web-processing industries – and thus increasing sustainability, the company says.

With all of this, quality assurance in the film and packaging industry leads to improved environmental footprints in production processes and products along the entire value chain.

Legislative decisions are propelling the change

Manufacturers of film and flexible packaging have been under enormous pressure to substantially increase the environmental sustainability of their products. Across Europe, the EU Commission’s “A European Strategy for Plastics in a Circular Economy” from early 2018 and the “Directive (EU) 2018/852 Amending Directive 94/62/EC on Packaging and Packaging Waste” has been setting the agenda: packaging should be 100% recyclable, reusable or biodegradable. In Germany, this has resulted in the German Packaging Act (VerpackG) that came into force at the beginning of 2019.

There is also pressure coming from the branded goods industry. It is giving manufacturers of flexible packaging until 2025 to deliver novel packaging solutions that are 100% recyclable, reusable or biodegradable. According to BST eltromat, the special challenge in the development and manufacture of new packaging materials is that not only do they have to hold up to the performance and visual quality of the previous materials, but they must allow for the same level of efficiency in their production.

New requirements for quality assurance

The new materials, including recyclates, have special characteristics that impose new quality assurance requirements – for example, on web guiding or on the surface and print inspection. BST eltromat says it meets these requirements in part with adjusted web guiding systems, sensors, and inspection systems.

An example of this is the Digimarc barcodes that are being used increasingly in the field of manufacturing packaging. In contrast to the previous one- and two-dimensional barcodes, Digimarcs are components of the packaging design and thus are not immediately discernable to the human eye. They are usually integrated into the artwork on the packaging in several places. Digimarcs can be read from practically any angle and at the highest machine speeds. They also make it possible to automatically sort plastic packaging from recycling companies’ sorting units and send it directly to the recycling stage.

Digimarcs also create new challenges for quality assurance. BST eltromat is tackling these challenges with its iPQ-View for digital web monitoring and iPQ-Check for 100% inspection. Both solutions are modules of BST eltromat’s iPQ-Center, which includes four seamlessly integrated high-end modules for quality control and management in web printing, and whose functionality covers virtually all of the market’s current requirements.

Artificial intelligence in error classification

In mid-November 2019, BST eltromat took part in the fourth gathering of the Converting 4.0 network at Windmöller & Hölscher (W&H) in Lengerich. The event dealt with data communication across process boundaries. BST eltromat highlighted how bringing together quality data leads to greater efficiency and security as well as more convenience and sustainability, provided the information is available in synchronized form.

For example, artificial intelligence can significantly benefit process analyses in terms of error classification. Currently, members of the Converting 4.0 network are developing scenarios that describe how more added value can be generated by taking additional process and material data into account. Here, too, the future promises to be exciting, the company says.

Industry 4.0 can contribute to increased sustainability in the manufacture of flexible packaging in many other ways. For example, in the framework of its cooperation with SeeOne Vision Technology, a manufacturer of surface inspection systems based in Florence, Italy, BST eltromat is linking information from film extrusion with quality data from the printing process. SeeOne’s systems detect surface defects in different materials such as films, metalized films, paper or cardboard, and use artificial intelligence to classify them as holes or inclusions, or as foreign matter such as insects or dirt. The findings gained from the surface inspection can be used in various ways to optimize production processes.