Last September we met the chairman of Parksons Packaging, Ramesh Kejriwal to get his views on a number of industry and technology issues. Kejriwal spoke about the new Sri City plant coming up near Chennai – the company’s first plant in South India and its inauguration in January or February.

Now the first phase with about 100,000 square feet is ready and the plant is to be inaugurated on 24 February 2017 with a galaxy of industry leaders in attendance. Jean Pascal Bobst managing director of Bobst, Stephen Plenz member of the management board of Heidelberg and Vindi Banga managing director of Hindustan Unilever are among the luminaries expected to take part.

Now the first phase with about 100,000 square feet is ready and the plant is to be inaugurated on 24 February 2017 with a galaxy of industry leaders in attendance. Jean Pascal Bobst managing director of Bobst, Stephen Plenz member of the management board of Heidelberg and Vindi Banga managing director of Hindustan Unilever are among the luminaries expected to take part.

The plant itself will convert 500 tonnes of paper and board a month initially and scale up to 1,000 tonnes a month by the end of financial year 2017-18. Right from the start it will contain a Heidelberg CX102 7-color plus coater combination press with full UV curing and Inpress controls and an array of Bobst diecutting, foil stamping and folder gluer machines. The second Heidelberg CX102 will most likely be installed in the first half of the 2017-18 financial year. The plant will produce both monocartons and E-flute litho laminated cartons.

launch of Gecko food grade ink by

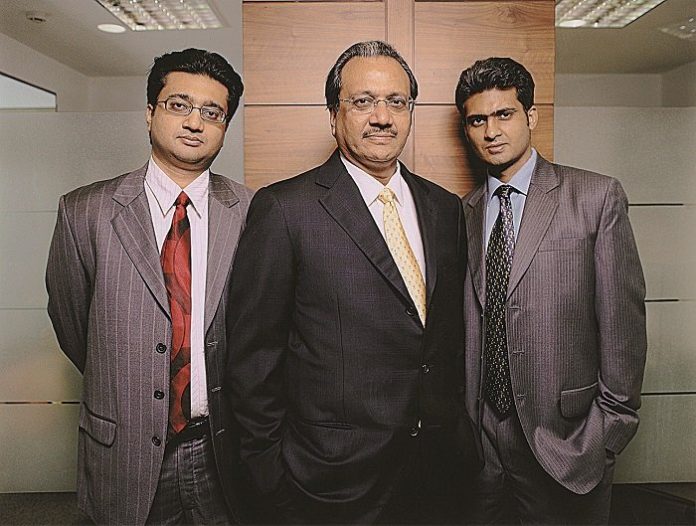

Parksons Packaging. Photo PSA

Ramesh Kejriwal says that the overall strategy of Parksons Packaging given the context of industry growth and demand is to continue to plan for 20% CAGR growth. He expects that after the demonetisation of 8 November 2016, “the economy will pick up soon, the biggest challenge is unhealthy competition and sometimes unreasonable pressure from customers.”

West, North, South and East

Parksons Packaging has also ordered its first highly configured press for its brand new Guwahati project in which it hopes to take on the challenge of commencing production in March 2017 with one printing line and the ancillary converting equipment. Kejriwal says, “In the future the group is looking at both digital printing and converting as well as larger format presses. However, a great deal depends on how the economy and industry perform. In addition I do feel that apart from more capex, investment in human capital and training is necessary. The packaging converters must also learn from and bring in the good manufacturing practices from other industries.”