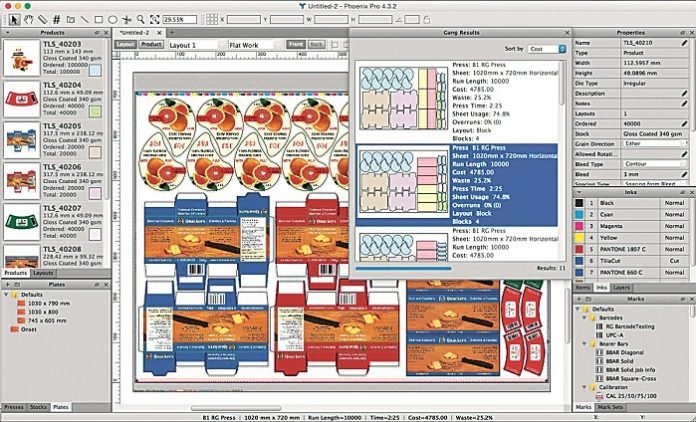

Fujifilm Graphic Systems Europe has announced a distribution agreement with Tilia Labs to incorporate Phoenix imposition and planning software for packaging applications into its print production solutions portfolio. Phoenix is a JDF-based platform that seamlessly integrates with Fujifilm’s XMF Workflow to provide increased automation and production efficiencies for a variety of applications such as packaging, labels and tags. It offers a wide range of imposition features including irregular shaped step and repeats, automatic artwork to die layout alignment and mark management. The software’s planning capabilities optimize the way jobs are collated or ganged for printing based on minimizing waste or maximizing printing speeds. This ganging functionality supports true shape nesting and automatically provides users with different options to arrange jobs. Phoenix also enables print service providers and converters to quickly generate accurate job estimates and drastically reduce preparation time and waste.

John Davies, business strategy and marketing manager, Print Production Workflow Solutions, Fujifilm Graphic Systems Europe, comments, “We are very excited to be introducing Phoenix into the European market following the agreement we signed a few months ago with Tilia Labs to distribute Phoenix in Japan. We are committed to continuously enhancing our suite of print production solutions for packaging applications, and the combination of the advanced functionalities within XMF and the imposition and planning capabilities within Phoenix is another strong step in this direction. The sophisticated job collation, auto layout and irregular nesting functionalities offered by Phoenix perfectly complement XMF’s powerful print production features.”

He continues, “XMF Workflow incorporates the Adobe Mercury RIP Architecture and is one of the most sophisticated print production platforms available today on the market. Due to the integration with Phoenix, XMF Workflow is now well suited to address the demands of packaging, folding cartons, labels and wide format production.”

Sagen de Jonge, CEO at Tilia Labs, says, “Phoenix planning and imposition functionalities combined with the advanced RIP and processing capabilities of Fujifilm’s XMF Workflow, will benefit print service providers and converters by increasing automation, streamlining the production workflow and ultimately reducing costs.”

Davies concludes, “Establishing a partnership with a company such as Tilia Labs, which has an in-depth knowledge of the packaging and label industry, is an important step for Fujifilm and supports our ongoing commitment to develop solutions for the packaging market. Integrating Phoenix into Fujifilm’s product portfolio will allow us to further improve our capability to target the packaging and folding carton segment with XMF and provides an ideal platform for us to expand our workflow offering in the future.”

Fujifilm will be featuring Phoenix at Stand A34 Hall 9 at Labelexpo Europe 2015, which will be held from 29 September to 2 October in Brussels Expo in Belgium. According to Fujifilm India, the integrated XMF Workflow integrated with Phoenix will also be made available in India in the future.