Domino Printing Sciences (Domino) is announcing the introduction of a new, compact monochrome inkjet printer, the K300, to the Indian market at Labelexpo India. First introduced at LabelExpo Americas in September 2024, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analog printing lines.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, senior product manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

“We will showcase our new label print monitoring and inspection systems for the N730i, developed in collaboration with Domino Group Company Lake Image Systems — the R-Scan. It gives converters the confidence they need to produce high-quality labels, and allows for unattended operation while enhancing efficiency, and reducing waste,” said Russell Weller, head of digital color, Domino Printing Sciences.

The launches will be showcased at LabelExpo India, hall 9, stand A22, from 14 to 17 November 2024. In addition to the K300 monochrome printer showcase, Domino’s LabelExpo India stand will feature demonstrations of the Domino N610i digital label press and K600i monochrome printer alongside automated machine vision from Domino Group company Lake Image Systems. The show will also see the introduction of a cost-effective hybrid printing system, the Domino N610i-H, which will be demonstrated as part of a UV Graphics Technologies line.

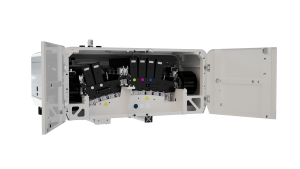

Building on the success of Domino’s K600i print bar, the K300 monochrome inkjet printer can be incorporated into analog printing lines to customize printed labels with variable data, such as best-before dates, batch codes, serialized numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54 mm – offers enhanced flexibility about positioning on the line, including the opportunity to combine two print stations across the web width to enable the printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customization process in a manufacturing facility, lowering inventory costs and reducing waste.”

Domino is looking at Asia, with offices in India, China, Korea, and Indonesia and a strong network of distributors and partners across the region. Weller says, “We are putting more and more people on the ground. Last year, we were the first big player to establish a subsidiary in Indonesia for our coding and marking business. South-East Asia is a key region. The well-established Indian market is among the most dynamic and successful regions for us. Not just as a key market from a sales point of view, it is a hub for development and product manufacturing. We have been in India for a long time, and we will continue to invest to support that growth.”