The International Business Summit and Exhibition on injection and blow molding and PET held in Mumbai on 12 and 13 June 2025 was excellent. It attracted approximately 450 participants and more than 50 exhibitors of raw materials, processing equipment, converters, and recyclers. Four learnings stand out to me from the conference.

The first is that the plastics processing industry in India is growing steadily, and is likely to continue to grow with considerable innovation, structure, and exports for the foreseeable future. The second learning is that the injection and blow molding, and the rigid packaging segments of the plastics industry are possibly more structured with larger investments and companies compared to the flexible packaging industry. I am sure some readers will contradict my observation and point out that there are many smaller players in plastic injection too – but the fragmentation and multiplicity of vendors is more visible in Elite’s flexible packaging event that takes place later this year, in September, in Mumbai.

My third learning from the presentations and discussions at the ElitePlus conference is that the most exciting segments of injection and blow molding in India are largely rigid plastic containers and PET bottles. Although there are numerous plastic manufacturers of everything from automobile components, cellphones, electronics, furniture, and construction products, the mobility and auto components segments were most visible at the event – both significant and growing contributors to the Indian economy.

My fourth learning is that the industry is alive and active in the sustainability of plastic production, its use, and recycling. Presentations at the conference ranged from well-argued explanations that the problem of plastic waste as a whole is trivial to another interesting presentation that suggested that plastic packaging has an unnecessarily poor and undeserved reputation in contrast to industries such as fast fashion, to those that presented numerous innovation in saving energy and materials to the once-in-a-lifetime opportunity for inclusive waste collection and recycling not unlike other historical socio-economic achievements in our past.

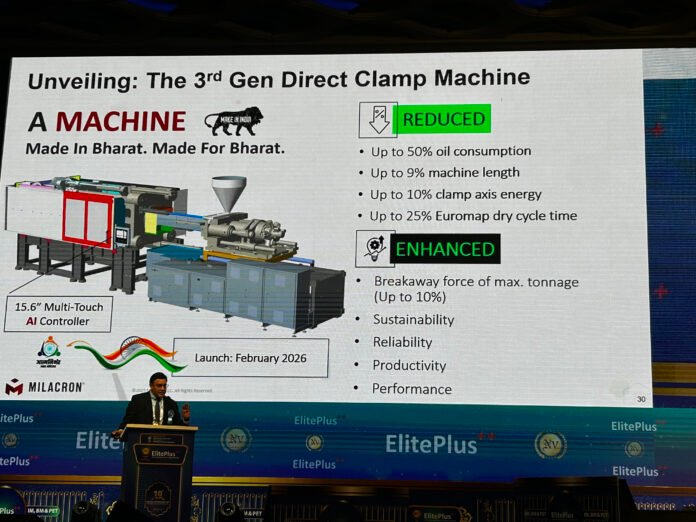

What follows next is an article on injection molding innovation by Milacron, as presented at this year’s ElitePlus event. In future articles, I hope to write more about the innovations discussed at Elite concerning injection molding, blow molding, molds, and sustainable and recycled polymers and additives.