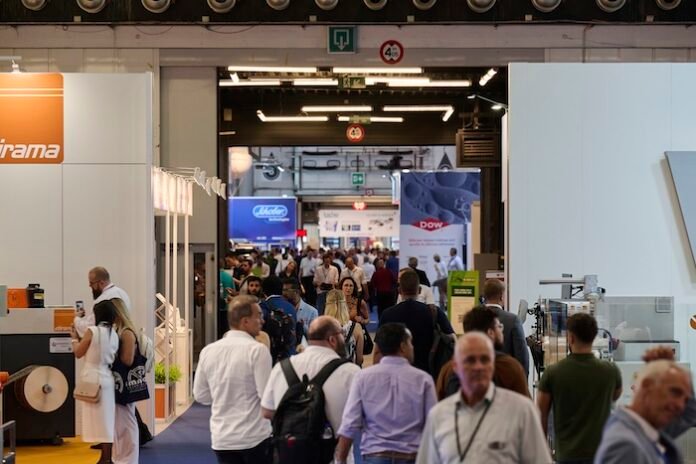

Labelexpo Europe 2025, to be held in Barcelona from 16-19 September at the Fira Gran Via, is set to highlight a noticeable shift within the label and packaging sector. Writing in his column, Will Parker, senior packaging executive and Labelexpo Ambassador, said while the show has long been a platform for innovation in narrow- and mid-web printing, this year’s edition underscores a growing focus on folding cartons—an area gaining renewed attention across Europe and the UK.

The shift is being driven by a mix of regulatory changes and evolving consumer preferences. As Parker points out, fiber-based packaging is moving into the mainstream, supported by national policies and market demand for recyclable, plastic-free formats. In this context, folding cartons—particularly those produced inline—are being viewed as an increasingly viable solution, especially for converters looking to diversify beyond labels.

Established technology, renewed relevance

According to Parker, inline carton production is far from new. For over a decade, food-to-go applications in the UK have relied on inline flexographic systems to produce folded, glued and coated fiberboard formats efficiently. Similarly, the beauty and personal care sectors have adopted hybrid workflows for producing embellished sleeves, rigid boxes and gift cartons, often completed in a single pass.

What has changed is the urgency around adoption. Rising energy costs, SKU proliferation and stricter environmental regulations have brought inline production to the fore, prompting both label converters and sheet-fed carton printers to reassess their options.

Regulation and consumer expectations

Parker highlights that regulatory frameworks such as the EU’s Packaging and Packaging Waste Regulation (PPWR), the UK’s Plastic Packaging Tax and new Extended Producer Responsibility rules are collectively steering the market toward fiber-first solutions. These shifts are echoed by growing consumer demand—particularly among younger demographics—for sustainable, mono-material packaging with a minimal environmental footprint.

These developments are influencing packaging decisions across sectors including food, pharmaceuticals, cosmetics and e-commerce, where brands are actively seeking alternatives to traditional plastic packaging.

A natural extension for label converters

In Parker’s view, label converters are uniquely well-positioned to enter the folding carton space. With established strengths in short runs, inline printing, embellishment workflows and automation, many already possess the infrastructure and expertise needed to pivot into carton production with minimal disruption.

Technologies from suppliers such as Canon Edale, Gallus, OMET, MPS, Mark Andy and Bobst are facilitating this transition, enabling printing, die-cutting, gluing and finishing to occur in a single pass. This streamlines production, reduces waste and shortens lead times—factors that are particularly valuable in today’s market.

Sheet-fed printers adapting too

Parker also notes that legacy sheet-fed carton producers are increasingly looking at inline technology as a complement to their offset capabilities. By shifting shorter or high-variation jobs to inline platforms, they can ease pressure on litho lines, eliminate finishing bottlenecks and improve delivery timelines.

This hybrid model—blending inline and sheet-fed workflows—gives converters the flexibility to handle a wider range of job types, while offering customers quicker turnaround and more sustainable production options.

Where demand is growing

Inline carton production is gaining ground in categories characterized by SKU complexity and lower-volume runs. Parker points to pharmaceuticals and nutraceuticals, which require versioning and compliance features; beauty and skincare, where packaging often supports the brand experience; and food-to-go, where barrier-coated, recyclable formats are increasingly favored. E-commerce and D2C brands are also driving demand for short-run, giftable secondary packaging.

Across these segments, the ability to respond quickly while minimizing waste aligns well with the capabilities of inline workflows.

A converging market

For Parker, Labelexpo Europe 2025 represents more than just a new location—it reflects a larger shift in the industry. The inclusion of folding carton technology at this year’s event suggests that the boundaries between label and carton production are becoming less distinct. In many cases, the same presses and workflows can serve both markets, particularly for converters focused on agility and sustainability.

As Barcelona prepares to host the event, Parker sees it as a timely moment for converters, brand owners and technology suppliers to reassess their production strategies and explore opportunities at the intersection of labels and cartons.