Offset printing for flexible packaging and labels is not a new idea, but in Barcelona, one could see its resurgence. Our visit to the Rotatek factory, located in a modern industrial area in the northern part of the city, approximately 30 minutes from Labelexpo, revealed an automated 9-color Rotatek Universal offset and flexo sleeve combination press with a 850 mm width, being built for a leading converter for special applications. Rotatek’s customers and distributors from around the world took the opportunity to visit the factory and have a look at the Universal 850 on the assembly floor.

This is a fully automated technology press with components from the leading European and global providers proven on multiple substrates for labels, flexible packaging, folding cartons, in-mold labels, pharma packaging, and inserts. It uses an interchangeable light offset sleeve system for which Rotatek has a global patent. A completely built Universal 850 unit was also shown at the Rotatek-Vinsak stand at Labelexpo.

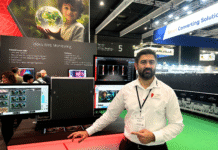

The factory visit also revealed that the Rotatek Brava wet offset semi-rotary and rotary press is being completely revamped with a new design by the company’s Barcelona team. The unique semi-rotary and rotary Brava wet offset press allows printing in both semi-rotary and rotary systems with an inline finishing unit. Useful for medium and short print runs, its semi-rotary unit system permits format changes without the use of any tools or having to change the cylinder. According to the Rotatek-Vinsak managing director, Ranesh Bajaj, a key factor in the resurgence of offset presses for flexible packaging is the increasing requirement for short runs and lower cost of origination using offset plates. “With live demos at our booth and the chance to visit our manufacturing site, visitors are getting a complete view of our capabilities and commitment to innovation,” he added.

The factory visit also revealed that the Rotatek Brava wet offset semi-rotary and rotary press is being completely revamped with a new design by the company’s Barcelona team. The unique semi-rotary and rotary Brava wet offset press allows printing in both semi-rotary and rotary systems with an inline finishing unit. Useful for medium and short print runs, its semi-rotary unit system permits format changes without the use of any tools or having to change the cylinder. According to the Rotatek-Vinsak managing director, Ranesh Bajaj, a key factor in the resurgence of offset presses for flexible packaging is the increasing requirement for short runs and lower cost of origination using offset plates. “With live demos at our booth and the chance to visit our manufacturing site, visitors are getting a complete view of our capabilities and commitment to innovation,” he added.

At the Rotatek-Vinsak stand at the Barcelona Fira, the Vinsak Label-Decore, a modular label finishing machine designed for high-quality embellishments and flexible configurations, was shown. The live demos showcased the label converting, decoration, premium embellishment, and finishing capabilities of the machine.