Struktol Company of America, a leading innovator in polymer additive technology, has highlighted its innovative VMO Series, an advanced family of melt flow modifiers designed to optimize polypropylene (PP) processing, quality, and versatility for the general market.

Featuring a proprietary blend of fatty acid derivatives and vis-breaking technology, Struktol’s VMO Series delivers rapid and precise melt flow index (MFI) adjustments, addressing the needs of compounders and processors looking to streamline manufacturing and enhance product performance.

Offered in an easy-to-handle off-white to beige pastille form, this melt flow modifier features a low-odor formulation that includes an odor neutralizer, allowing for high-quality, neutral-smelling finished compounds.

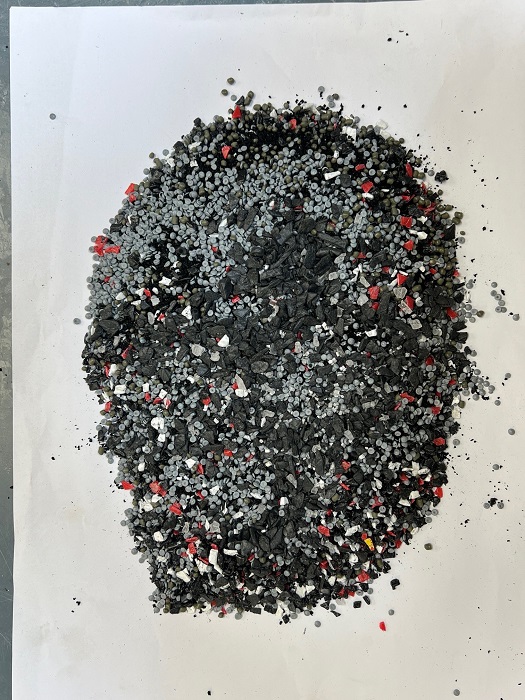

The masterbatch approach ensures convenient dosing, safety, and precise incorporation into polymer systems across extrusion, compounding, or injection molding operations. Compatibility with polypropylene containing up to 35% polyethylene (PE) extends the reliability and performance of the VMO Series in both pure and recycled applications, even in the presence of contamination or intentional blending, supporting sustainability initiatives and greater use of recycled content.

The VMO Series is available in a range of activity grades (VMO 058, 108, 208, 308, 408), providing tailored solutions for different melt flow targets and processing requirements. This multi-grade approach gives customers the flexibility to match modifier activity with specific formulation and throughput goals, enabling the consolidation of raw materials and minimizing the need to inventory multiple base PP MFI grades.

The Struktol VMO Series empowers manufacturers to accelerate throughput rates, enhance manufacturing efficiency, and lower overall costs. Effective at low addition levels, and a storage stability of at least two years ensures long-term usability, dependable inventory management, and consistent product supply, with industry-standard 50 lb. bags and 2,000 lb. skid packaging formats.

Each grade maintains a stable and predictable dropping point between 74–86°C and a specific gravity of 0.98–1.0, allowing for reliable operation across a wide array of polymer formulations. The masterbatch contains Struktol’s proven lubricant and process aid technologies, promoting uniform integration, reduced risk of additive segregation, and improved compound quality.

The Struktol VMO Series supports circular manufacturing models and closed-loop recycling efforts. Backed by Struktol’s comprehensive technical services, R&D, and quality assurance teams, customers benefit from expert support and reliable performance.

With the VMO Series, Struktol says it demonstrates its commitment to providing advanced additive solutions that increase productivity, simplify production, and deliver maximum value for the plastics processing industry.