On the second day of the FoodTekPack Conference, one of its important sessions, ‘Designing for Sustainability – New recyclable structures for flexible packaging’ took place with Dr Madhab Chakraborty moderating and Dr Ajay Kumar Nema of Alok Masterbatches as the lead speaker. The panelists in the session were Nayandeep Banerjee of Pernod Ricard, Himanshi Mahajan of Mother Dairy, Abhishek Arora of LT Foods and Rajesh Kumar Srivastava of the Uflex Chemicals Business.

Dr Nema’s presentation highlighted the challenges and constraints in developing recyclable films and laminates for several key types of food product packaging. His comprehensive presentation discussed the attributes of food products and the levels of complexity they require in barrier properties to prevent degradation during their shelf life. He presented solutions that packaging designers can consider, their relative recyclability, as well as the constraints of the collection systems in place.

“Where the fat contents are quite low in food products such as processed meat, processed dry foods and also in non-food home and personal care, these are generally the low complexity applications. The medium complexity applications are confectionery, yoghurts, cheese, and snacks, where the barrier requirement is comparatively higher,” he explained.

“The high complexity applications include processed foods, and also tea and coffee. Coffee is particularly important because it is very sensitive to moisture and fat. In these applications, a high barrier complexity is required because a small amount of moisture may degrade or disintegrate the basic properties or aroma of the food product. While shelf life is increased due to these barrier properties, the complexity of the material gives rise to the complexity of its sustainability or efficient recycling.”

Apart from addressing the practical challenges of collecting and recycling flexible packs, Dr Nema went on to present three possible solutions and the new structures and systems needed for each type of material. “For instance, a packet of chips is generally just thrown away anywhere by the consumer, and there are numerous such examples. Most of the time, 80% of this packaging goes to the landfill, and while 12% is incinerated for energy, only 8% is recycled,” he said.

“On the other hand, PET bottles are invisible in the landscape, because they have some value for collectors, but that is not the case for flexible packaging. Even if they collect 5 or 10 kilograms of flexible packaging, they will still not get even 5 or 10 Rupees.”

He added that we have to distinguish between categories of recycling, such as those where only 2% is being collected and recycled to a similar or lateral application, as opposed to materials being collected and downcycled to a lower application, such as bricks or building materials. In plastic waste management, there are only three solutions: end–of–life solutions, either biodegradable or bioplastics, or fully recyclable solutions.

Thus, complex structures such as Pet/Poly; Pet/Met pet/Poly; Pet/Foil/Poly; BOPP/PE; and, BOPP/MET BOPP/PE containing materials with varying melting points, are generally not recycled but after collection, are used in pyrolysis or energy recovery, or may be used in cement plants and road construction.

Biodegradable materials

Dr Nema stated, “When we talk about biodegradable material, we say it is wonderful, very good material, fantastic. But the terminology used is confusing: biodegradable, biocompostable, industrial compostable, aerobic biodegradation, anaerobic biodegradation, oxo-degradation, and nobody understands what is what.

“Ultimately, at the end of the day, there is no collection medium. If I am making a chip packet out of biodegradable material, there is no collection medium or waste stream in place. Just throwing the material and having it degraded by the environment is not possible.”

Dr Nema added that if a biodegradable material is used, after use, it has to be digested in a proper waste stream where there is a mechanism to digest it, and it should be 100% compostable. If the material is oxo-degradable or even fully degradable, it requires the medium to degrade or it will not degrade.

For biodegradable materials, you need to have the collection infrastructure and the composting medium. Each material has its own degradation mechanism – aerobic, anaerobic or industrial, and each mechanism requires a different pH, soil, or enzymatic action, and time interval for completion. To disintegrate the material completely is not very easy.

In addition, for food applications using biodegradable materials, the barrier complexity is difficult to achieve, while the desired coatings for printing and gloss add to the cost, which is already a negative parameter for this solution.

Mono-material recyclable solutions

The third type of solution, based on mono-materials, permits the use of the recycled materials as many as seven times for a similar application. Dr Nema showed the structure of a PE/PP laminate, which with appropriate research and development, acquires barrier and other properties needed for food packaging.

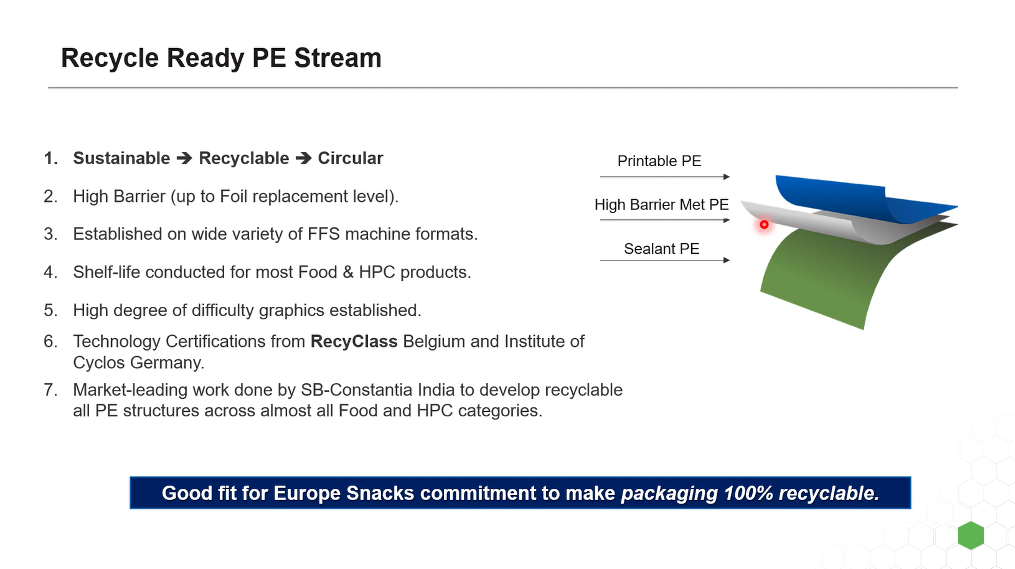

As a practicable solution for snackfoods and across almost all food, home and personal care categories, he showed an all PE structure with printable PE on the outside, a barrier layer of metalized PE and an inner layer of PE for good sealability. This 100% recyclable market-leading solution by SB-Constantia India received technology certifications from RecyClass Belgium and the Institute of Cyclos in Germany, and is established on a wide variety of FFS machine formats.

In the ensuing panel discussion, moderated by Dr Chakraborty, Abhishek Arora of LT Foods brought up some of the challenges of recyclable flexible materials such as BOPE for functionality and pouch formation, adding that bio-based materials face both cost and scalability issues. For a brand owner using mono-material MDO-PE, there can be challenges of haze, gloss, and sealing, he said.

Rajesh Kumar Srivastava, of Uflex Chemicals, spoke about the increasing availability of water-based functional coatings for barriers and other properties for both flexible and paper materials, adding that the selection of raw materials is critical, especially in food applications. While paper-based materials have established recycling streams and are perceived as environmentally friendly, the panel and Dr Nema suggested that double-sided coated paper cannot be recycled, and for the foreseeable future, only medium barriers are achievable.

To a question from the audience, Nayandeep Banerjee of Pernod Ricard responded on the basis of his experience in creating a sustainable laminate for noodles using a BOPP/CPP laminate. In 2022, when this work was done, the cost differential was just 5 to 7%. He added that the selection of materials and resin manufacturers is critical to achieve sealing initiation temperatures.

Himanshi Mahajan of Mother Dairy emphasized the necessity of designing for recyclability, the need to continuously research PE replacements, and also the use of AI in packaging structures and design optimization. The discussion among the panellists and the audience went further by discussing the various types of coatings, barrier materials, functional adhesives and costs that are increasingly being explored by packaging designers keen to build recyclability into the initial use of flexible structures.