As India’s plastics and packaging sectors look to the future, manufacturers are investing in advanced processes such as machine direction orientation (MDO), in-mould labelling (IML), and smart factory automation. While these technologies promise greater efficiency, sustainability, and product innovation, they also introduce new static and contamination risks that can quietly erode quality, increase rejections, and chip away at the financial return manufacturers expect from their capex.

At PlastIndia 2026, from 5-10 February, Meech Shavotech India will demonstrate how integrating proven static management and web cleaning solutions from day one can protect these investments, ensuring that productivity gains and material savings are realised in full rather than lost to stoppages, rework or waste.

The hidden costs of unmanaged static

Meech analysis has revealed that unmanaged static can cost businesses as much as £13,000 (₹16 lakh) per month in wasted materials and lost production, based on an audit of a single traditional 1,200mm wide printing press. In new processes, these costs can be even higher.

New blown film technologies like MDO optimize raw materials like polyethylene (PE) by improving stiffness, transparency and heat resistance, enabling lightweighting that reduces material use and transport costs.

However, the four key processes in this technology, heating, stretching, annealing and cooling, each generate significant static charges and consequent side effects. However, its four key stages – heating, stretching, annealing and cooling – generate significant static charges. Combined with additives such as slip agents, this leads to powder and flake build-up on rollers, forcing lengthy cleaning stoppages. Where cleaning is skipped, print quality suffers and reject rates rise.

“In India’s high-volume production environment, these inefficiencies can escalate quickly,” said Ravi Shinde, India sales manager at Meech Shavotech India. “India’s manufacturers are ready to adopt the technologies that will define the next decade of plastic packaging innovation, but without also investing in advanced static control and web cleaning, the return on that investment is put at risk from day one.

“Treating static and contamination issues only after they cause issues is an expensive approach. Global markets have already gone through the costly trial-and-error phase with emerging technologies like MDO, so Indian manufacturers don’t need to repeat those mistakes. The proven solutions already exist, and the fastest route to efficiency and realising the cost benefits is adopting them from day one.”

PlastIndia 2026 exhibitor highlights

Meech will exhibit at PlastIndia 2026 at stand H4GM-F20, showcasing advanced static management and surface cleaning solutions including:

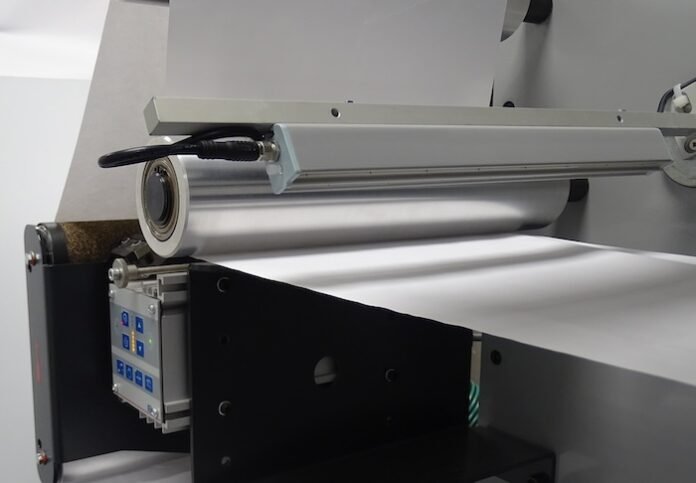

- CyClean non-contact web cleaning system: CyClean is engineered to tackle contamination challenges in converting and labelling, efficiently removing loose, dry debris from the web surface. Using advanced computational fluid dynamics, it extracts unbonded particles down to 0.5 micron without touching the substrate, helping manufacturers protect delicate coatings, maintain high line speeds and reduce waste.

- CyClean-R narrow web non-contact web cleaning system: For narrow-web applications that rely on low tension to handle thin or sensitive materials, CyClean-R provides a targeted solution. Positioned on the roller where web stability is greatest, it overcomes the limitations of low-tension running for effective cleaning without the risk of web damage. Available in single- or double-sided configurations, the system uses positive and negative airflows to strip away the boundary layer and capture contamination for vacuum extraction, incorporating Hyperion 924IPS bars for robust static control.

- Hyperion 994CPD compact perforation detector: Meech’s new Hyperion 994CPD has been developed in direct response to industry demand. The 994CPD reliably uses Automated Baseline Current Detection (ABCD) to accurately detect perforations in real time – for example, to count tear-off perforations on bags, or to catch packaging defects. It is powered by 24VDC, allowing for easy integration with most industrial systems. The 994CPD can detect perforations without contacting the material, ensuring no risk of damage even at high speeds. This is important for delicate films, hygienic products or medical-grade materials which must remain sterile.

- Hyperion SmartControl Touch: As Industry 5.0 accelerates the shift towards smarter, more connected production environments, SmartControl Touch gives manufacturers centralised oversight of their static control ecosystem. Users can monitor, control and adjust the performance of multiple connected Hyperion products in real-time through an integrated touchscreen or remotely via a mobile phone, tablet, touchscreen or monitor.

Meech International is a global name in static control, surface cleaning and air technology. Headquartered in Oxfordshire, UK, the company manufactures products in both the UK and the US. Meech Shavotech India, based in Pune, serves as the company’s dedicated regional presence, providing specialist sales and technical support to help Indian manufacturers maximise performance and reduce operational losses with solutions that can be installed in original manufacturing equipment or added to existing lines and plants.

Meech products add value to production in the automotive, battery, converting, electronics food and drink, medical, pharmaceutical, packaging and textile industries.