Ram Navami on 30 March 2023 was an auspicious day in several respects, especially for HBD Packaging in Greater Noida. It stormed and rained in the evening as the electricity went and came. The generators were switched on, and so was the new RMGT 7-color plus coater full UV press that printed its first sheets on packaging board. There is every reason to hurry as there are a substantial number of short-run carton jobs lined up for the new press in the new 970 mm format.

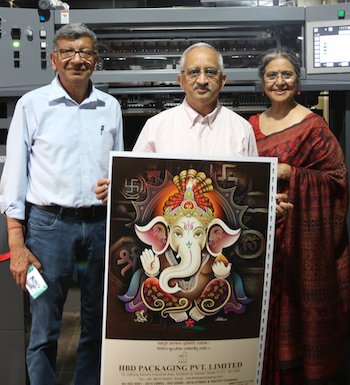

Photo PSA

Family, friends, partners, colleagues, and engineers gathered in the late afternoon and evening. Three generations of the family were present. There were many reasons to celebrate and to be grateful as this long ago ordered machine finally arrived and was installed in record time by the synchronized Provin engineering team. It was quite remarkable to see how quickly the press came into operation to print sheets in full hairline register, the spectrophotometer readily scanning first sheets, and the console cameras revealing the movement of the paper from the feeder to the print units.

For most of the Indian carton industry which never takes anything for granted, the past three years have been eventful. The economic and emotional scars are difficult to enumerate but the overall context is that the resilience of an industry deemed essential – helped to keep shelves and eCommerce everywhere in the country stocked throughout the lockdowns and the various stages of recovery.

Photo PSA

For a conservative company such as HBD, there have been many investments and 30% growth post-Covid, mainly in the converting section over the past several years but the last brand-new multicolor packaging press came several years ago. Window patching, litho-lamination with automated stacking, new die-cutters, and folder gluers have come in regularly necessitated by the increased trend for more micro-fluted litho-laminated cartons. These have compelled the company to expand both in terms of equipment and working space – upward in the first instance in the present factory and soon to a new nearby plant where most of the corrugated operations will be shifted.

The new RMGT 7-color plus coater has interested us because it is a machine that will consume less power in its operation and because its interdeck UV LED lamps combine the possibility of also being used for conventional UV curing if needed. After the coater, the end-of-press curing will be done with conventional curing systems since the volume and cost of LED-based coating is excessive. One looks forward to learning more about how carton packaging can reduce its carbon footprint – both in its key printing process and the overall plant that will soon be adorned with solar panels managed by a leading energy supplier.