Leveraging over 40 years of packaging and blowing expertise, Sidel has extended its blowing range with the new EvoBLOW XL machine for large containers. With 75% of parts in common with the existing EvoBLOW range, the solution builds on Sidel’s performance and has been designed for multiple markets. Future developments are also taking place to extend the technology to address hotfill products.

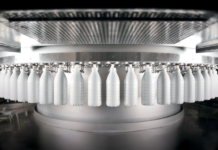

With ever-changing consumer demands, the packaging industry requires solutions that can handle larger formats while being user-friendly and ergonomic. Sidel offers more flexibility for the packaging industry by launching its new blowing machine to produce larger bottles with the highest level of production efficiency. EvoBLOW XL provides packaging quality, safety and sustainability benefits that can also be emphasized with its connectivity to the Evo-ON software suite, which supports customers to optimize production lines.

Flexible production

Available as a stand-alone or integrated combi solution, EvoBLOW XL is said to be a versatile machine that can provide a high level of quality and extended performance for a wide range of bottle formats for up to 8L to 10L. It features flexible oven configurations with a wide choice of bottleneck dimensions which demonstrates its flexibility to handle many types of large bottles. The EvoBLOW XL complements Sidel’s existing complete line capabilities for large containers.

EvoBLOW XL is also said to achieve high production efficiency with the highest market blowing outputs, up to 18,000 bottles per hour (bph) and 98% proven overall equipment effectiveness (OEE). The new machine has been designed to offer a high level of flexibility for customers and offers several attractive features for efficient changeovers, ensuring a user-friendly process. Equipped with an ergonomic embedded mold handling tool, heavy mold positioning is simplified and ensures safety. Additionally, the mobile mold storage unit provides fast and safe access to molds close to the machine. EvoBLOW XL can also be integrated easily with other Sidel solutions such as its latest ultrarapid changeover system bottle switch.

Sustainable solution

As the demand for rPET continues to rise, EvoBLOW XL has been developed to manage the challenges associated with rPET grades and possesses proven process capabilities from virgin PET to up to 100% rPET, the press release said. Additionally, EvoBLOW XL offers lightweighting opportunities for customers which can provide significant savings on PET costs and minimize CO2 emissions. This includes the possibility to switch from HDPE to PET large bottles to further reduce the carbon footprint. Further sustainability benefits are also achieved through the new design of blowing circuits and valves which help reduce energy consumption.

While being a sustainable solution, EvoBLOW XL also helps to be cost-effective, maintaining impressive levels of efficiency with the highest market outputs.

Sidel’s EvoBLOW XL ensures the blowing process to secure an attractive bottle design with user-friendly solutions. The machine uses an optimized process and blowing curve with its new powerful blowing circuit and valves to deliver perfect material distribution at the fastest speed with 1,500 bph per mold while securing low blowing pressure and the highest bottle quality.