Solvay, a supplier of specialty polymers, has introduced a new Omnix high-performance polyamide (HPPA) compound family based on a minimum of 33% recycled content, consisting of 70% PIR/PCR recycled resin is highly secured and has a controlled process by the supplier. The innovative Omnix ReCycle HPPA technology follows the company’s One Planet roadmap towards continuously improving the environmental footprint and circularity of its product portfolio.

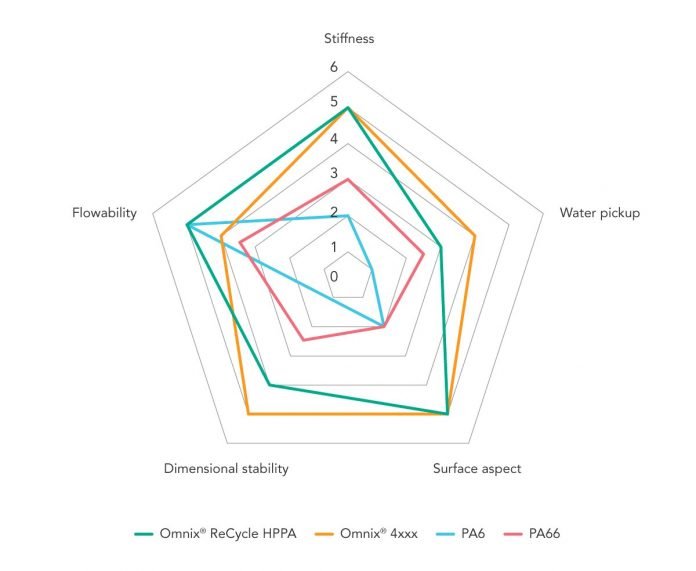

“As Solvay’s first-ever recycled-based HPPA with 50% glass fiber reinforcement, Omnix ReCycle is a real breakthrough in the market of polyamides for household appliances,” says Claire Guerrero, global marketing manager for Packaging Segment and Sustainability at Solvay. “It combines the outstanding mechanical properties of virgin semi-aromatic HPPA with better flow, lower water pickup and best-in-class surface aspect. In addition, its unique performance and sustainability profile offers an attractive material solution for brand owners and manufacturers who seek to increase the recycled content in their products without compromising dimensional stability, high stiffness, impact resistance and processability.”

The recycled content of Omnix ReCycle saves resources and results in a significantly lower carbon footprint than virgin HPPA, thus showing a 30% lower global warming potential (GWP). At the same time, it has an ideal fit for replacing lower-performing polyamides (PA) and metals.

For instance, household appliances deliver higher durability than those provided by standard PA6 or PA66 polymers. This helps OEMs reduce breakage and damage returns while meeting the growing awareness of consumers for longevity and lower environmental impact in their product choices. With its excellent surface appearance, the new recycled-based HPPA can also eliminate the need for painting, which adds to its overall sustainable benefits and facilitates the end-of-life recyclability of applications in an increasingly circular plastics economy. Another target is wearing and tear resistance for lightweight interior components in transportation and automotive.

Solvay’s Omnix ReCycle can be processed on standard injection molding equipment, including the use of water-heated molds. Following selected customers’ successful sampling and approval, the new sustainable HPPA material is commercially available worldwide.