Apex International, a global specialist in anilox solutions and services, will highlight its complete range of anilox lifecycle solutions in PlastIndia 2026, reinforcing its commitment to supporting the growing needs of the flexible packaging industry.

At stand C4, hall 12, a key focus at PlastIndia 2026 will be Apex’s strong local manufacturing and refurbishment capabilities in India. All Apex anilox rolls and sleeves are manufactured and refurbished locally, enabling faster turnaround times, responsive service support, and global quality standards tailored to the Indian and regional markets, the company said.

Advanced anilox solutions and services

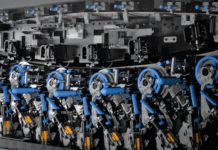

Apex will present its complete anilox lifecycle management offering, covering everything from new anilox roll and sleeve manufacturing to cleaning, inspection, auditing, and refurbishing. These solutions are designed to help converters achieve consistent print quality, reduce ink and material waste, and improve overall operational efficiency.

While anilox remain central to Apex’s expertise, the company continues to expand its portfolio to support modern print environments. Visitors can explore anilox protection and cleaning solutions, advanced composite sleeves, sleeve protection covers. The HD sleeves are highly durable, lightweight with extended lifespan, and excellent dimensional stability.

Apex will also highlight its sleeve protection covers, designed to safeguard anilox rolls and sleeves during handling, storage, and transport, helping prevent damage, contamination, and premature wear while ensuring consistent on-press performance.

Apex has also newly launched laser cleaning machine which offers a safe, chemical-free, and highly effective method for restoring anilox cell volume and cleanliness, supporting consistent ink transfer and longer anilox life.

Another key highlight will be the Apex Anilox Audit Program, developed to help printers get the best performance from their anilox inventory. Through detailed audits, Apex evaluates anilox condition and performance to ensure optimal ink transfer and print consistency. Regular audits also enable early identification of potential issues, helping prevent unplanned downtime, reduce repair costs, and extend the lifespan of anilox rollers.

Apex will showcase its globally recognized GTT engraving technology, designed to deliver precise ink transfer, reduced ink consumption, and exceptional print consistency. Apex engravings integrate seamlessly with existing press workflows and support a wide range of plate resolutions, hybrid screening technologies, and substrates. By improving versatility and reducing downtime, Apex solutions help converters achieve reliable performance across diverse print applications.

To demonstrate real-world results, Apex will display print samples for both wide-web and narrow-web applications. These samples highlight how printers can achieve high-definition, gravure-like print quality using a limited set of anilox rollers, while maintaining the efficiency and simplicity of flexographic printing. The showcased samples underline Apex’s ability to deliver precision printing across a wide range of packaging applications.

Speaking about Apex’s participation at PlastIndia 2026, Mangesh Bhise, director sales for Asia Pacific and Middle East at Apex International, said, “Today’s converters are looking for partners who can support their performance goals, not just suppliers of products. At Apex, we deliver global standards in precision and sustainability, backed by local manufacturing and services that keep print operations future-ready.”