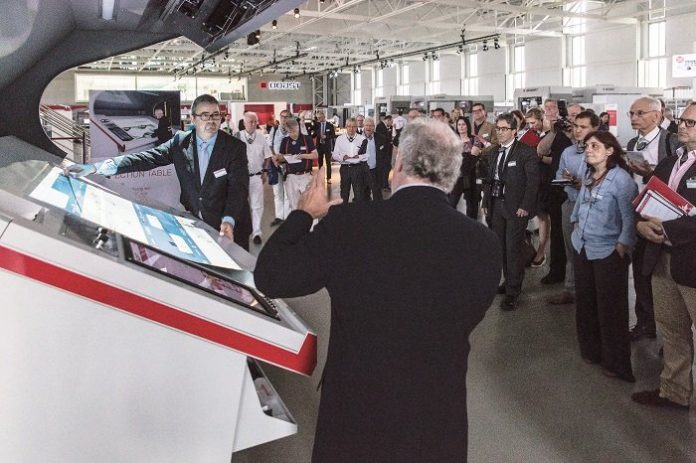

Bobst held its Open House event, Competence 18, from 5-8 June 2018 at the Competence Center of Bobst Mex, Switzerland. The event attracted over 600 visitors including many leading packaging and label manufacturers and converters from the industry. The event promised to show the ‘Solutions for the challenge of tomorrow,’ addressing key trends facing packaging converters, such as the need for shorter runs, greater versatility, eCommerce, and constant innovation.

Philippe Milliet, head of Business Unit Sheet-fed, said, “We develop our solutions with our customers in mind and all the direct feedback we receive at events like this helps us to improve even further. Many attendees were surprised by the pure breadth of what Bobst offers. Bobst is an expert in substrate processing, converting and printing, and it was very rewarding being able to demonstrate several of the company’s most innovative solutions first-hand, and to talk with visitors about the very tangible difference we can make to their businesses, now and in the future.” Attendees enjoyed live demonstrations of selected key Bobst machines, and were introduced by Bobst Services to exciting developments.

There was also a live demonstration of folder-gluer Expertfold 165 with the automated packer Speedpack, the natural extension of a corrugated folder-gluer. Speedpack bundles a large range of box formats and types, from solid board up to double wall corrugated board boxes, delivering perfect and smooth high-speed packing.

Live demonstrations of Mastercut 106 PER and Mastercut 145 PER showed the most automated and productive diecutters in the market. The machines deliver fast, uninterrupted production, unbeatable productivity in size IIIb and size VI respectively rendering quality fi nished product. The Matic system on the Mastercut 106 PER drew particular attention. It allows the highest degree of automatic operation available on any die-cutter.

In addition, attendees saw Expertfoil 142 in action, claimed to be the only genuine size VI hot- foil-stamper in the world, and the only one with 600 tons of embossing pressure. It allows users to put more blanks on every sheet – up to six in format VI instead of only two in format IIIb – hence, margins can be increased on a whole range of jobs.

Masterfold 230 with its modular design, single box set-up and reliability, was another popular machine demonstration. With Gyrobox XL, it can rapidly produce complex designs in a single pass, particularly eCommerce boxes.

On the printing side, a static module of M8 Lemanic inline flexo printing press was available at the event. Folding carton converters observed its manufacturing and advanced technologies, and recognized the convenience of inline printing and converting, from a web substrate. Converters saw the technology as ideal for both web to sheets and web to diecutting, for short, medium and long runs. With printing samples available at the event, converters inquired about the simplicity of the flexo process vs offset, and how to achieve the print quality on display.

Visitors witnessed the ease of using fl exo technology compared with offset, and the greater consistency in the end result. They also heard about recent evolutions in prepress, plate and anilox technologies and the improvement in the performances of printing presses that deliver these consistent results with limited intervention of operators. A brief was shared about THQ FlexoCloud, a fixed color palette solution for corrugated board post print applications, considered a quantum quality shift in post-print flexo. For post-print fl exo on corrugated board, THQ brings quality at lower costs in one pass.

The Extended Color Gamut (ECG) process and the digitization of color matching were discussed at the event. Converters observed that fl exo can achieve what offset in the past years had tried for years with limited success. They recognized the advantages in flexibility and time-to-market when using the ECG technology in combination with Digital Automation in flexo presses.

Several of Bobst’s service offerings drew attention, in particular the new Digital Inspection Table, a novel technology designed to drive quality assurance, productivity and virtually remove print production errors. The Tooling solutions on show were also an attraction for die-makers and converters alike, with continuous demonstrations of the various pieces of equipment that optimize productivity on any die-cutter.

“These Open House events really do feel like inviting guests into our home,” said Milliet. “It is such a privilege for us to be able to demonstrate our passion and innovation to people who can really benefit from it, and we are thrilled with the positive comments we have heard from all the attendees.”