At the K2022 fair in October, Colines, which was also present at the Elite conference in Mumbai in September, exhibited with live demonstrations – one of its flat-head extrusion lines, the AllRollEX 3000 mm. We had an opportunity to meet Giuseppe Maddaluno at the company’s stand with the ongoing demonstration of the AllRollEx 3-meter wide cast line running daily from 11 am to 3 pm using its new Mastermind profile and line management system. In addition, Colines showed stand-up pouches produced using cast MDO-PE films produced using its latest generation MDO.

The AllRollEX cast line shown at K was producing a 12 µ stretch film containing up to 30% PCR material obtained by chemical recycling from ExxonMobil. The stretch film was specified to be capable of over 400% ultimate strain and a 300% wrapping consistency. In test runs carried out at the fair on an Estl test machine, the ultimate strain values exceeded 400%, with a wrapping consistency better than 300%. In addition, Colines showed the new generation of its Allwrapper ‘any-bundle’ wrapper using stretch film in place of shrink film.

Colines handles recycled material for its cast and blown film lines, with the help of the Gneuss RSFgenius Melt Filtration system. This RSFgenius system is fully automated and can process up to 40% recycled content in the manufacture of 10 µ stretch film. The constant melt pressure offered by the RSFgenius system and its efficient self-cleaning function is a major benefit when using recycled materials. Gneuss also had its own stand at K.

Colines shows cast MDO-PE films stand-up pouches

Photo Packaging South Asia

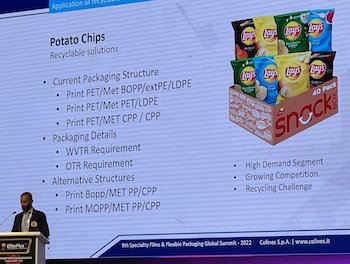

As we learned at the Elite Conference in Mumbai in September, from the presentation of Francesco Peccetti the sales manager of Colines, the company is a pioneer in the engineering and manufacture of machine direction orientation (MDO) units that can add desirable properties on film lines. In his Elite presentation, Peccetti spoke about the about the new ‘Pure’ structure for barrier films and some of the company’s other innovations including its latest generation MDO that incorporates an IR heating unit.

The company which manufactures a diverse range of plastic extrusion equipment has approximately fifty installations in India. Colines’ distributor in India, Mumbai based HiTech International was present at both the Elite Conference and at the K exhibition – in the person of Sagar Engineer.

Colines’ expertise in cast extrusion or flat-head lines combined with MDO has evolved since its first stand-up pouches produced using an MDO-PE film obtained on a flat-head extrusion line. At K, the company showed stand-up pouches produced using a polyethylene-based film extruded with cast technology and its most recent generation MDO in line.

Seen as an alternative to MDO-PE films produced on blown film lines and also films based on PP and PET, the PE-based extruded film with cast technology is seen as an innovation that generated great interest at K. This is because an MDO-PE cast film is seen to have better optical properties and gloss values and is also much easier to both seal and to recycle with melting temperatures significantly lower than other polymers.

This MDO-PE cast film line was developed because an important end customer wanted an alternative to producing blown PE film with an inline MDO. Apparently, Colines announced a year ago, the successful development of a polyethylene-based cast MDO film featuring high mechanical and optical properties, and decorated using offset printing. The company says its next goal is to optimize the efficiency of its cast line to produce both MDO-PE film and the welding PE film that, in some cases, is necessary for the end products.

At K, where its stand was extremely busy with visitors often having to wait to enter for their appointments, Colines also presented its new Mastermind, a profile and line management system developed in cooperation with Elav, which became a subsidiary of the Gruppo Colines in 2006. The AllRollEX 3000 mm-wide cast extrusion line demonstrated at the stand was being manageed by the Mastermind automated electronic managment and control system.