Apex International will underline its commitment to sustainability at this month’s drupa 2024, when the global leader in anilox, metering and embossing solutions showcases the data-backed credentials of its innovative GTT engraving technology under the EcoProven banner.

Supported by years of data and customer testimonials, the company will use the world’s largest print and packaging exhibition to demonstrate how the system is a critical part of sustainable practices across the offset, flexo wide web, and corrugated print sectors.

Joris Cabri, Apex VP of Sales for Europe & Africa, said: “In an era where companies use buzzwords to pay lip service to their sustainability agenda, Apex stands out by substantiating its claims with solid evidence. We are excited to shine a spotlight on our well-established GTT engraving and to demonstrate the technology’s positive contributions to the printing industry at this year’s drupa.”

From stand A10 in Hall 10 of the Messe Düsseldorf, the Apex team will showcase how GTT engraving contributes to environmental sustainability and cost efficiency. “We will spotlight to drupa visitors our EcoProven initiative and significant breakthroughs in sustainable printing, living up to our ethos that ‘Only our quality should touch the Earth’,” Joris said. “We will demonstrate how we are developing innovations that meet today’s sustainability challenges, and our commitment to cleaner, more responsible printing solutions is clearer than ever.

“At drupa, we are excited to reveal robust data that shows how the EcoProven benefits of our well-established GTT technology resonate across the corrugated, flexo wide web, and offset industries,” he said.

Better laydown, reduced ink usage, enhanced opacity

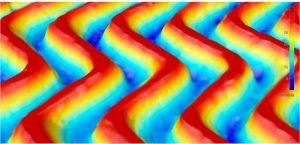

With its innovative open slalom cell geometry, GTT from Apex has transformed ink application in printing by allowing for better ink laydown, significantly reducing ink usage while enhancing opacity and shine.

Enhanced ink efficiency provides richer colours with less waste – for example, in white opacity applications, users can achieve superior laydown with one-hit white, using technology that benefits both the environment and their budgets. Similarly, in offset applications, GTT allows for more shine with less lacquer, enhancing cost-efficiency and reducing environmental impact.

“The technology is a cornerstone of our EcoProven initiative, where real-world applications from our global customer base substantiate every claim,” added Joris. “One notable success story involves a major customer who reduced their ink consumption by more than 12% after adopting our patented engraving, without any sacrifice or compromise in terms of print quality.”

Joris said Apex’s presence at drupa 2024 is a testament to the company’s dedication to harmonizing printing technology with ecological preservation. “By focusing on data-proven technology and technological advances like GTT, Apex is paving the way for a future where efficient and more sustainable printing processes are the norm,” he said. “As the industry continues to evolve towards achieving these sustainability goals, Apex remains at the forefront, championing innovations that deliver performance and environmental benefits.”