Presenting at the recent Elite Conference in Mumbai, Anan Hiyasat, the Dubai-based IMEA region manager and director of MEA for Uteco, started by reiterating that packaging has emerged as a key enabler in achieving the modern objectives of safety and hygiene. He further cited the growth of packaging volumes, particularly in emerging markets, as well as the increasing number of SKUs and promotional products leading to shorter print runs.

Hiyasat went on to warn, “If plastic were a country, it would be the fifth largest emitter of greenhouse (GhG) globally. By 2025, plastic production will be two times bigger in the market and three times more present in the ocean.”

Packaging producers are taking remedial action through innovations based on the elimination of packaging where possible; reducing it to the minimum; reusing and recycling, and finally, redesigning and rethinking the packaging eco-system. He showed alternatives that include paper-based materials, mono-material film structures, and those based on compostable and bio-based plastics.

The core of Hiyasat’s presentation for the converters in the audience was the new Uteco OnyxGo CI flexo press that makes short runs for flexible packaging viable with low waste, energy, and solvent consumption. He suggested that with the set of three ‘Active Pack’ technologies for makeready, curing, and ink – the new press that was announced at the recent K exhibition in Dusseldorf will enable savings of more than Euro 100,000 annually. He said that with the Active Pack, the OnyxGo press pays for itself with its savings in energy and material consumption. Industry experts see this as an innovative press that is relevant to the Indian market.

Active Start comprises an automatic recognition of the flexo plate’s 3D characteristics that are digested by a ‘Super Algorithm’ and sent to the setup console and to the variable parameters that can be quickly and automatically adjusted. Apart from repeatability and quick makeready with low waste, this technology should yield useful real-time data.

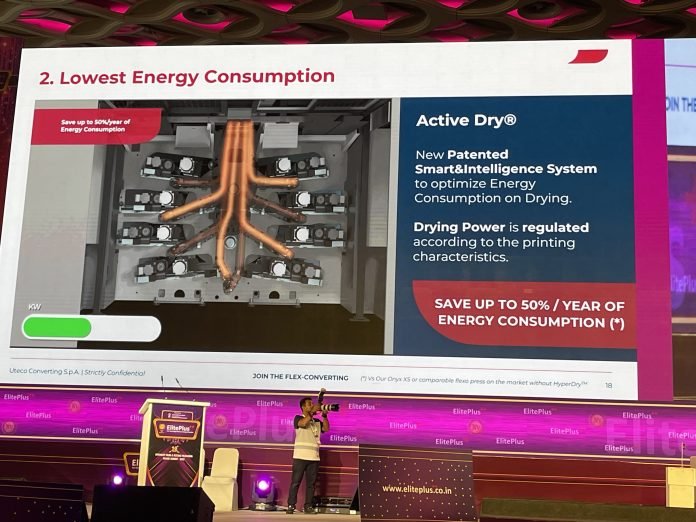

The approach to smart curing called Active Dry optimizes the drying power systems by using algorithmic print characteristic data by adjusting the flow to each printing deck according to its need. This is claimed to enable savings of up to 50% in energy costs.

The Active Ink function also pumps inks according to the print characteristic algo and with a short path since the ink dispensers are positioned on the side of the CI drum. Uteco says that this could save up to 40% of the ink and solvent consumption and considerable energy as well.

In addition, Hiyasat showed a video demonstrating the ergonomic and high-tech control panel and interface that actually adjusts its height to the operator’s convenience. There are several other ergonomic features that make the press safer and easier to operate, clean, and maintain. The noise level of the press is also lower than 80 decibels.

The presentation also revealed Uteco’s new Flex-Converting alliance where the company will expand its portfolio with GAP extrusion blown film lines that can go up to 9 extruders and 27 micro layers to produce thinner and lighter materials. The alliance also brings liquid packaging lines into the group’s offering.