True to this year’s motto ‘Transition in packaging,’ Syntegon will present process and packaging solutions centered around the future topics of sustainability and automation at Fachpack from 27 – 29 September. An integrated system solution for packaging pistachios will be the highlight at stand 1-204. An Elematic 2001 wraparound case packer will be also on display, which complements Syntegon’s versatile system competence. “We want to support food companies in making their production fit for the future. The integration of flexible, automated systems and sustainable technologies contributes significantly to this goal. This allows manufacturers to react even faster to future trends,” explains Torsten Sauer, project manager of Sustainability at Syntegon.

Automated solutions through system competence

Photo Syntegon

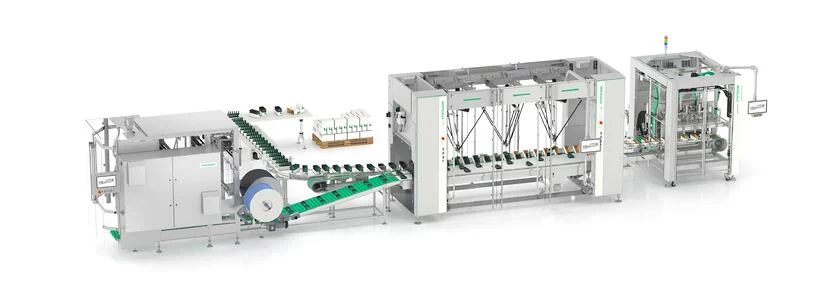

Syntegon has been engineering robotic solutions for decades. And the Covid-19 pandemic has significantly accelerated the mega trend toward automation. The focus at Fachpack will therefore be on the European premiere of the RPP robotic pick-and-place platform – the modular platform complements packaging lines by taking over product handling and/or feeding. The robotic solution will be on display at the stand as part of a turnkey system in combination with the SVE 2520 DZ vertical bagger and the Kliklok ACE carton erector.

On site, the SVE 2520 DZ vertical form, fill and seal machine weighs MagNuss brand pistachios (part of EUROFOOD Handelsgesellschaft mbH) before packing them into Doy bags. The highly flexible machine also processes all other common bag formats. The RPP pick-and-place platform picks up the doy bags which are transported flat, positions them correctly, and places them five at a time upright in cardboard trays that have been performed on the Kliklok Ace. The Ace covers both glue closure and glueless lock-style closures, providing sustainable options for different carton formats. The individual components of the exhibited line can be configured flexibly, giving manufacturers many options to respond to changing market trends with a wide range of packaging styles, formats, and materials.

Seamless integration into existing systems

Syntegon also demonstrates its system competence with the Elematic 2001 wraparound case packer on display, which is now also available with a Beckhoff control system in Europe. As the solution can be seamlessly integrated into vertical and horizontal systems, manufacturers can add a Syntegon case packer to their packaging lines, thus increasing the level of automation in their production. Fast, tool-free format changes and more than 100 case designs allow manufacturers to respond quickly to changing market needs with the Elematic case packer. Additionally, all Elematic machines can reliably produce sustainable cases from recycled cardboard or grass fiber corrugated boards.

The future is sustainable

By the end of 2022, all Syntegon machines for food packaging will be able to process sustainable materials. “We’re already thinking about tomorrow – our Kliklok Ace carton erector, for example, creates paper trays for cookies, offering an attractive alternative to conventional plastic trays. And also the exhibited SVE processes not only plastic, but paper-based materials into pillow bags for frozen foods, as well as stand-up bags or doy bags for dry foods,” Sauer explains.

In 2021, Syntegon presented new concepts for structured paper pods and blisters formed on the TPU form, fill and seal machine. Just a year on, the company announced cooperation with contract packer Truvant, who applies the solution for various customers. Visitors to Fachpack can experience the paper solutions at the company stand. Syntegon will also exhibit new sustainable coffee packaging made of mono-material that can be processed into recyclable bags on the new PMX packaging machine.

Closer collaboration with customers thanks to Service Agreements and Digital Solutions

Innovations in the area of Services and Digital Solutions are another focus of the trade show stand. Syntegon now offers revised Service Agreements on different levels including services such as maintenance, spare parts management, remote service, and training. The flexible approach enables support at a fixed price that is specific to individual needs. Part of the Service Agreements is Synexio, a cloud-based software solution for the acquisition and evaluation of machine and production data. With the generated real-time data, companies are able to streamline their maintenance processes and enhance their overall production efficiency.

Photo Syntegon

European premiere – new Syntegon Robotics RPP pick-and-place platform.

Live system demo – Integrated line consisting of the SVE 2520 vertical form, fill and seal machine, Syntegon RPP, and Kliklok Ace carton erector.

Sustainability – alternative packaging concepts for coffee, dry and frozen foods replace conventional plastic.