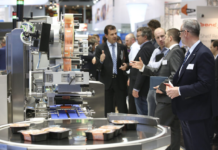

Coesia, a global leader in industrial and packaging automation, will unveil its latest innovations at Ipack-Ima 2025, scheduled from 27 to 30 May at Fiera Milano, Italy. Located in Hall 7, Stand A46-B45, Coesia and its companies will showcase how they are transforming production across the FMCG, food, home and personal care, and industrial sectors with scalable, sustainable systems.

Coesia companies ACMA, Atlantic Zeiser, Citus Kalix, FlexLink, Norden, and Volpak, along with partners ERRELLE and PWR, will demonstrate how automation can spur productivity, cut costs, and future-proof operations. The exhibition will feature advanced machinery, smart services, and digital platforms designed to meet the evolving needs of global manufacturers, the company stated.

“At Coesia, we are shaping a new era of industrial production, where automation is no longer just a support function but a key driver of progress,” Alessandro Parimbelli, CEO of Coesia, said. “The technologies we are presenting at IPACK-IMA are built to reduce manual intervention and empower operators to focus on value-adding activities. We are leading the evolution of automation by developing intelligent, self-operating production systems that meet the demands of tomorrow’s manufacturers.”

Cross-industry automation and packaging solutions

Under the theme ‘Automation Evolution – The New Era of Industrial Production,’ Coesia will present a broad range of technologies designed to redefine packaging performance, adaptability, and sustainability, with a strong focus on automation and flexibility.

ACMA will highlight the FP EDGE with PAPER KIT, a high-speed horizontal form-fill-seal solution engineered for sustainable packaging. Capable of processing materials with up to 95% paper content, the FP EDGE matches the performance and product protection of plastic-based flow packs. Operating at speeds up to 150 metres per minute, it features ergonomic reel loading, pneumatic web control, optional laser coding, and an intuitive design for fast changeovers and continuous production.

Atlantic Zeiser will introduce CodeVault, a secure software platform for code generation and serialisation management. Built to comply with GS1 Sunrise and 2D code regulations, CodeVault helps brands streamline production and meet new traceability requirements with ease.

Citus Kalix will showcase the KX803 automatic tube filling machine, designed for the pharmaceutical and beauty industries. Offering tool-free cleaning, intuitive operation, and rapid changeovers, the KX803 runs at speeds of up to 80 tubes per minute, ensuring quality and flexibility while reducing downtime and training needs.

FlexLink will launch a new condition monitoring solution integrated with its X85 Compact Spiral Conveyor, collecting real-time health data from conveyors to enable predictive maintenance and avoid unplanned downtime. The X85 Spiral requires less than one square metre of floor space and, when combined with FlexLink’s DesignTool and QuickGuide components, delivers highly efficient smart automation for production lines.

Norden will spotlight its range of secondary packaging solutions for tube-filling systems, including the NC100 cartoner and NTP170 case packer. These solutions offer rapid format changeovers, a compact footprint, and high-speed performance. Norden will also highlight the NCE14 case erector and NCS14 case sealer for end-of-line automation, optimized for pharmaceutical packaging.

Volpak will present its flexible pouching technologies, including the SM+ platform, which can handle both pre-made and reel-fed pouches with quick changeovers and a modular setup. Volpak will also introduce its new Inverted Pouch format, designed for cleaner dispensing and improved product evacuation—combining consumer convenience with sustainable packaging appeal.

PWR, a Coesia partner, will feature the Smartline Robotic Packaging Solution, a compact and scalable pick-and-place system for the food industry. Designed for high-speed handling without heavy customization, the Smartline improves productivity, reduces costs, and simplifies packaging processes, making it an ideal solution for food manufacturers seeking flexible and efficient operations.