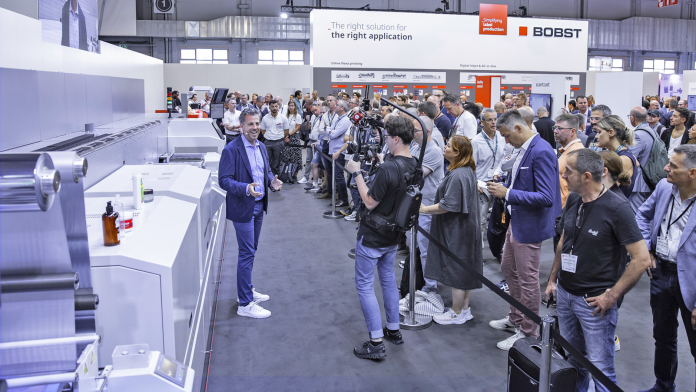

September saw Bobst take to the show floor at Labelexpo Europe 2023 for the first time since 2019. The Bobst stand shared four days of new strategic partnerships, collaborations and innovations, customer success stories, enriching networking, and live product demonstrations with the crowds of visitors.

Label solutions by Bobst

Bobst offers a complete product portfolio of future-proof label solutions strategically designed to combine automation, digitalization, and connectivity with the sustainability-driven needs of an ever-evolving market. From inline flexo to pure digital inkjet and All-in-One, its products cover printing, embellishment and converting technologies, the company said.

Inline flexo and digital technologies

During the show, Bobst showcased solutions made to simplify the label production process from end-to-end including workflow, connectivity, color management, printing, to converting, and quality control.

Visitors were able to experience live demonstrations every 30 minutes on both the Bobst Digital Master 340, the All-in-One modular and upgradable digital label press with quality control, and the Bobst Master M6, the highly productive inline flexo press for label and flexible packaging production.

Throughout the fair, Bobst’s experts guided attendees through its technologies for each and every step of the production process, from PDF design and preflighting to the final product, the company said.

Visitors got to see the many benefits of Bobst solutions first-hand, including;

Accessing production and performance data from a press from anywhere in the world with Bobst Connect. Increase machine productivity by monitoring equipment, viewing jobs, and identifying improvements on shopfloor tracking. Bobst Connect integrates seamlessly and complements the existing production management software, it said.

Managing a single seamless workflow integration across technologies and machines from PDF to twin PDF. Bobst offers label converters the possibility to create an open architecture supported by third-party solutions from industry partners, such as Esko, Scantrust, Bel, or CERM. Bobst says it can easily connect to other systems, facilitating a more streamlined influx of jobs.

The Bobst Digital Front End (DFE) pre-press software streamlines workflow from PDF to final label, featuring a user-friendly interface, Adobe RIP, PDF-based workflow, X-rite color management, and seamless integration into the existing processes for enhanced pre-press efficiency and productivity.

The digitalization of color management, which is key to predicting colors before printing as it enables color consistency and repeatability between digital and flexo. With Bobst oneECG Technology, one can manage color seamlessly, reducing waste and set-up time considerably.

Entering digital label production with no tradeoffs with Bobst Digital Inkjet Technology: Configuring a own press with a tailor-made solution, accessing 100% on-site upgradability to make your initial choice futureproof.

Bobst Accucheck Technology: With its self-developed inline calibration and quality control system, one can increase productivity, reduce waste and automatize the entire production process.

A global service organization

“With a total install base of over 1200 machines worldwide and more than 100 digital narrow-mid-web presses installed in the past year, Bobst is among the market leaders across technologies in the label market today,” said Matteo Cardinotti, GM & Global head of Narrow-Mid-Web Printing & Converting Product Line at Bobst.