Ryobi MHI Graphic Technology (RMGT) has announced the introduction of GEW’s LeoLED system as its factory-fitted UV curing solution for new sheetfed offset machines, with immediate effect. RMGT is said to have pioneered UV LED technology and introduced the world’s first LED curing system for sheetfed printing at drupa in 2008. This original innovation started a slow revolution for the printing industry, one that is now gathering an ever-increasing pace.

In pursuit of continuous technology improvement and after many months of assessment of all major UV LED manufacturers, RMGT formally adopted the high performance GEW product as its definitive new solution.

Katsushi Hirokawa, president at RMGT, explains the decision in detail, “RMGT is committed to building relationships of trust with customers, peripheral device manufacturers, and all others involved in the industry. We continually work with our partners to refine and perfect technologies and to bring innovative new products to the world of printing. Inspired by this corporate philosophy, we have pioneered LED UV, and it is our in-depth experience and knowledge of this technology that has enabled us to make a sound judgment about our future UV curing partner.”

The foundations of this new partnership were formed in 2018, following GEW’s drive into the sheetfed offset market. GEW is well known for its established, global dominance in the label and narrow web arena. The expertise gained from 30 years in this sector, and experience supporting all the major machine manufacturers, provided a strong base from which to expand into the offset business. The 2019 introduction of GEW’s compact, high-performance LeoLED UV curing system, which is perfectly suited to sheetfed applications, drew attention from RMGT’s distribution network, and this ultimately led to the first test installation at the company’s headquarters in Hiroshima in early 2020. The LeoLED system was exhaustively tested on several presses in multiple configurations, and the results surpassed all existing performance criteria.

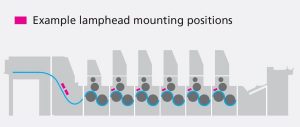

Robert Rae, managing director of Sales at GEW, comments, “This announcement affirms GEW as the leading supplier globally for UV LED curing systems. Our latest LeoLED system offers very high power and is used in one form for all markets and applications. This means that it is produced in high volumes, bringing outstanding reliability at a highly competitive cost. In a sheetfed environment, GEW’s Modular Lamp Array (MLA) allows any number of lamps to be positioned and quickly moved anywhere throughout the press. This means the same LeoLED product can be used for low, medium, and high-performance applications but arranged in single, double, or triple MLA configuration dependent upon the application and speed requirements – always guaranteeing performance. It is this concept that appealed to RMGT, both for ultimate reliability and for the flexibility of configurations across their wide range of presses.”

Reliability was paramount for RMGT when choosing a new UV partner. GEW have built a reputation for engineering and manufacturing UV systems to exacting standards, assembling and fully testing every UV system before despatch. But, unique to GEW, an IoT remote monitoring system reports all running conditions live and for the full-service history of the system. Service support specialists can easily detect and correct out of tolerance parameters and send remote updates anywhere in the world, guaranteeing the fastest and most precise service response in the industry.

The ability to easily adapt system configurations was a key consideration for RMGT. Gary Doman, International sales manager for Sheetfed at GEW, explains the company’s solution, “Multiple lamps are a requirement in more complex applications, and being able to move lamps around the press is a huge advantage for various processes. GEW lamps are designed with this in mind, and users can easily move lamps from the delivery to any interdeck position and back again. For coatings and other more demanding applications, the ‘Modular Lamp Array’ is used and offers more power, exactly where and when it is needed.”

Robert Rae summarises the new partnership: “GEW are proud to have been selected as the new UV LED partner of RMGT. We have a long history of producing reliable, high-performance products, and our fast, friendly and flexible approach to business has kept customers loyal to us over many years. We sincerely hope to continue this tradition with such a prestigious, highly regarded company as RMGT and to serve their customers as our own.”