In a major technological boost for the surface coatings industry, a new application has been devised based on an initiated chemical vapor deposition (iCVD) technique, which allows the

coating to be applied for original equipment manufacturer(OEM) or retrofit applications. Using very small amount of polymer precursors, a chemical reaction is carried out that covalently grafts an ultra-thin polymer film to any metal surface, such as stainless steel, titanium, copper, aluminium and even polymers and ceramics. This innovation by a US-based start-up, DropWise Technologies, will enable Henkel Adhesive Technologies drive its innovation capabilities forward, as it has signed a joint development agreement with the startup.

“Collaborating with promising startups that provide access to cutting-edge future technologies is an integral part of our innovation strategy. We can combine their unique technologies with our global market access and know-how in coatings to generate profitable growth for both the partners,” says Mike Olosky, corporate senior vice president and global head of innovation and new business development, Henkel Adhesive Technologies.

“We are very excited to be partnering with a global leader in metal surface treatment. Henkel’s strong track record of bringing new innovations to their customers will enable us to fast-track commercialization in key market areas,” says Adam Paxson, CEO of DropWise.

Increase in efficiency

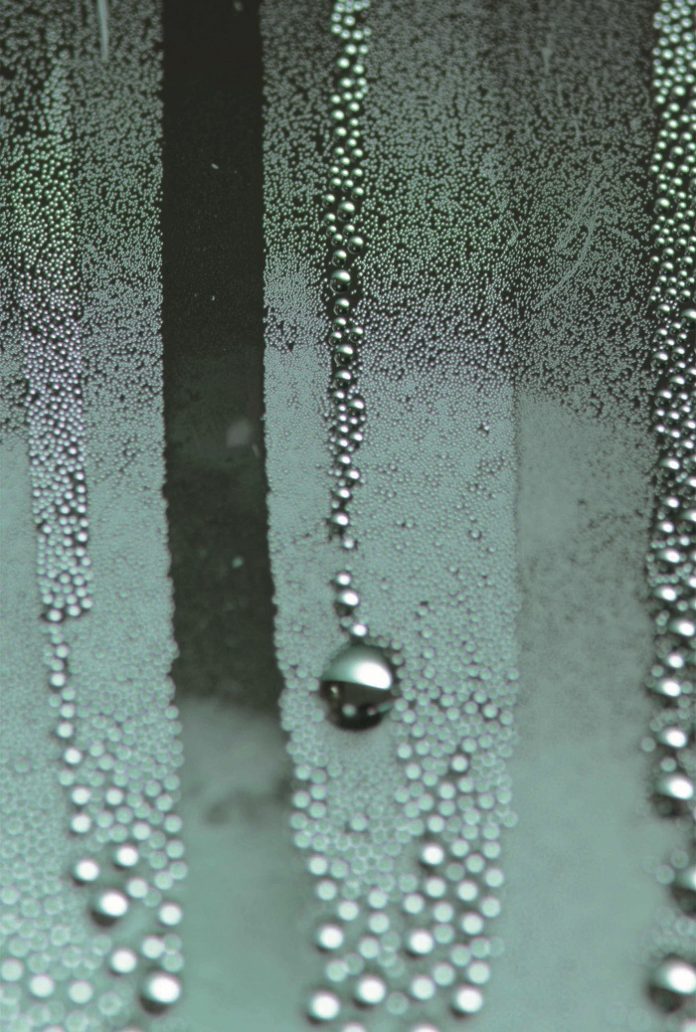

One fine example of DropWise’s hydrophobic coating is in condensing heat exchangers, where the technology increases the efficiency by eliminating the insulating film of liquid that typically builds up on the surface.

Increasing the efficiency of these systems allows for reductions in fuel consumption, emissions and coolant water use, particularly for thermal power plants, which are the largest contributors to global emissions and the second largest consumers of water.

Target applications include industrial heat exchangers such as steam condensers in power plants, heating-ventilation, automotive air-conditioning and chemical processes.