At Drinktec India 2025, held in Mumbai this November, we had an interaction with Nikhil Patkar, cluster portfolio manager at Tetra Pak India, who walked us through the company’s expansive stand and explained the depth of solutions on display. The tour offered a comprehensive view of how Tetra Pak is positioning itself as an end-to-end partner for the food and beverage industry, covering processing, packaging, distribution, automation, sustainability, and product innovation.

Processing: The first step in product creation

Patkar began by highlighting Tetra Pak’s focus on processing. Tetra Pak, he said, manufactures advanced processing equipment at its facility in Chakan, Maharashtra, which is then installed at customer locations across India and globally. “As part of our setup, what we are covering is processing, which is the first part of making any product,” he said. “From juice production to sugar-syrup preparation, the entire pre-processing ecosystem can be supplied by Tetra Pak.”

He emphasized Tetra Pak’s role in supplying critical processing lines for global beverage majors. “Most machines behind every Coca-Cola, Pepsi, or similar beverage are made by us,” Patkar noted, adding that even concentrate plants for these brands in India are supported by Tetra Pak technology.

One key exhibit was a sugar-syrup filtration line, designed to remove impurities and unwanted coloration from industrial-grade sugar. “This filtration ensures a crystal-clear sugar syrup, which is critical for products such as Sprite where clarity is essential,” he explained.

Packaging excellence

Moving from processing to packaging, Tetra Pak showcased its E3 Speed Hyper, described as the fastest aseptic carton packaging machine in Asia and among the fastest globally. “This is the fastest aseptic carton packaging machine,” Patkar said. “Despite its speed, its utility consumption and operational costs are low, and wastage is significantly reduced.”

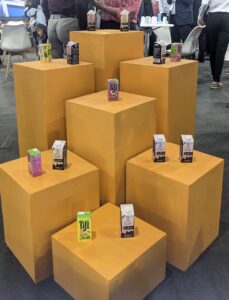

Photo- PSA

Compared to conventional systems, Tetra Pak’s equipment can deliver 20-30% lower energy consumption, he said. “Our designs are based on high-efficiency heating systems and optimized utilities, which directly reduce the total cost of operations for customers,” he explained.

Beyond packaging, Tetra Pak highlighted its capabilities in downstream distribution. From cap applicators and straws to end-of-line solutions, the company provides an entire ecosystem. Patkar stressed the importance of service and support. “We have an in-house field service team to support customers post-installation, helping them run their plants efficiently and maintain uptime,” he said.

Enabling startups and new product development

Photo- PSA

A particular section at the stand focused on startup enablement and innovation. Tetra Pak has been actively working with emerging brands. “We invite startups to pitch their ideas, and help them with formulation, packaging, and launch,” Patkar explained. He cited examples such as Zumi milkshakes and Oji, a product developed and launched in Guwahati, Assam. “Our packaging offers a shelf life of up to six months without preservatives, which is a huge advantage for niche products such as milkshakes or fruit-based beverages,” he added.

Its stand featured dedicated tasting and development zones showcasing lactose-free dairy, protein-fortified products, functional hydration drinks, and low-sugar formulations.

Sustainability and recycled content packaging

Tetra Pak highlighted India’s first carton package containing recycled content from its portfolio. In line with government mandates, Tetra Pak introduced cartons with 5% recycled content, manufactured at its facility. “We have already sold more than 2.5 billion packages with recycled content in India,” Patkar stated. He said 70-80% of customers have already adopted these packs, with wider adoption expected as regulations tighten, moving from 5% recycled content in 2025 to 10% by 2027.

Automation

Discussing automation in India, Patkar categorized customers into three segments—those with minimal automation, those adopting partial automation, and the top 10% moving toward full-scale digital and automated factories.

“For companies like Coca-Cola, PepsiCo, Amul, or Starbucks, automation is critical,” he said. “They want production data at their fingertips, on mobile, in real time.”

He shared examples of highly automated ‘dark factories’ operated by Tetra Pak globally. “We have factories running at four times the size of Amul with just 100 people. Everything is automated—people sit in control rooms monitoring systems,” he explained.

Patkar also shared Tetra Pak’s future roadmap in sustainable packaging. “Our cartons are made of paper, aluminium, and polyethylene,” he said. “We are now working to replace aluminium with non-aluminium, paper-based barrier materials.”

He said that such paper-based barrier solutions have already been launched in Portugal and are being introduced in other markets. “By 2030, our vision is to move towards packaging without aluminium-based barriers,” Patkar said.