The Zhongke India stand at IndiaCorr Expo 2017 in Greater Noida was a hub of activity with the entire staff on their toes, attending to visitors who flocked to the stand to see the machines on display. Along with four machines on display, the company also had a large screen video that showcased the functioning and operations of some of their machines. We witnessed live demo of various types of rigid carton boxes that were fabricated on the machines. Rohit Rajpal, director of Zhongke India gave us a brief on the machines on display as also the response they received at the show.

Zhongke India. Photo PSA

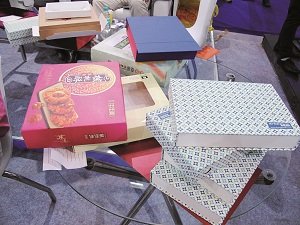

One of the machines on display was the ZK-5540WL fully automatic box-making machine, which is mainly applicable to B, E and F category corrugated paper, 12-20 PT ivory paper and 250-645 gsm gray board. The machine has been specially designed to add value to corrugated boxes that can be used for packing shoes, garments and toys among others. Rajpal showed us some mobile phone boxes, the inner layer of which was made of corrugated board with gloss-laminated carton paper on top that gave it a finish similar to rigid plastic. Zhongke is currently focusing on providing solutions for various value additions.

Zhongke offers the entire set-up for this kind of box-making operations, except printing. The suite of solutions include automatic line-cutting and grooving machines, semi-automatic lamination machines, hot foil stamping and diecutting machines, with customized solutions. According to Rajpal, Zhongke offers complete training, service and support for the machines that the company sells in India. The entire suite of machines is aimed at providing value-additions to corrugated boxes, which offers converters a cost-effective and durable rigid box solution. Zhongke India helps converters in setting up such an operation entirely or in parts depending on their existing infrastructure.

Rajpal said that Zhongke’s approach to the Indian market is based on its assessment of the specific needs of the industry here. With the fast growth of brands in the consumer products sector, the need for innovative packaging solutions will require a broad mix of solutions in which corrugation will have a vital role to play. Zhongke’s customized solutions in corrugation-based rigid box-making meet the needs of the fast-evolving market for branded products in India. This is also a very good solution for certain segments of the processed dry food industry although the potential for growth is vast where a combination of substrates can revolutionize packaging in any one or more segments.

Currently, Zhongke India ships all its machines to customers in India straight from its principals in China and the entire process is handled by following the most efficient and internationally accepted shipping methods. All specifications are set according to the need of the rigid box at the time of assembling the machinery at Zhongke India. Prior to shipment, Zhongke’s QC engineers do a pre-shipment check to ensure that the machine is delivered as promised by deploying the best logistic resources to handle transportation of the machine. A dedicated team of installation engineers and technicians at Zhongke India oversees the installation and also ensures seamless after-sales service to customers in India.