B&R has further expanded mapp technology framework with the new mapp Tweet function, which allows a machine application to send information via text message or email. The increased intelligence boosts machine availability.

Set up with just a few clicks, mapp Tweet can easily be connected to other mapp components. This enables the mapp AlarmX component, for instance, to automatically notify a maintenance technician when an alarm requires immediate action. mapp Tweet can supplement the message with additional information, such as troubleshooting instructions that allow the technician to quickly and efficiently resolve the cause of the alarm. This is an effective way to achieve a targeted reduction in machine down-time.

If the service technician isn’t on site, they can quickly connect via B&R’s remote maintenance solution in order to run diagnostics, adjust parameters and resolve the error. The solution utilizes the latest IT and security standards and allows for significant savings with low investment costs.

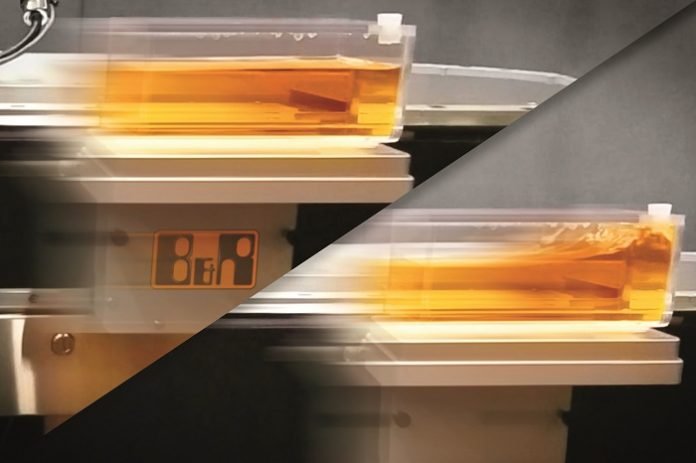

Boost productivity with anti-sloshing

With B&R’s industrial transport system, it is now possible to transport liquids quickly with no spills. SuperTrak is the only system on the market to offer anti-sloshing technology. This technology suppresses the formation of oscillations on free surfaces to prevent liquids from spilling over container edges during transport.

Specially designed movement profiles prevent the development of positive feedback loops on the surface of the liquid so that it remains calm during transport. This minimizes downtime and increases productivity when handling open containers.

Minimizing oscillations on the surface of liquids is particularly important in the packaging industry. The better you are able to control sloshing, the faster the products can be transported. B&R’s anti-sloshing technology also prevents the formation of air bubbles and foam. The downtime otherwise required to allow the liquid to settle is reduced drastically or eliminated entirely for a substantial improvement in packaging line productivity.