Pune-based Nichrome, a leading Indian packaging machines manufacturer, won the prestigious Pacmachine 2014-15 award for its high-speed Filpack Servo SMD oil packing machine. The presentation took place at an award ceremony on 10 October 2015 in Mumbai held in concurrence with India Pack 2015 and the World Packaging Congress 2015. The company has consistently won Pacmachine awards since 1994.

Introduced by the Indian Institute of Packaging (IIP) in 1992 the Pacmachine Awards recognize excellence in design development, innovation and import substitution in the packaging machinery sector. This year four categories were awarded including packaging machinery, packaging conversion machinery, other packaging machinery and supporting packaging machinery.

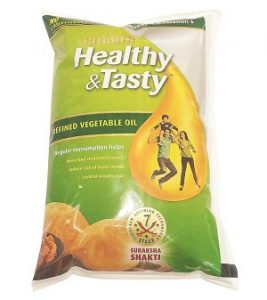

Nichrome Filpack Servo SMD for oil

Servo SMD for oil

The Filpack Servo SMD is the only double head machine in the market with an output of 100 packs a minute with a single operator required for double the output. CE certified with programmable logic control (PLC), servo motor driven with precise bag length and sealing mechanism it has an operator-friendly touchscreen. It also has motorized web tracking, jumbo film rolltrolley and can run 320 mm web widths compared to the existing 325 mm web widths.

Though the present rated output of the machine is 100ppm, it canreach120packs a minute with improved, better quality packing material. The other key features of this machine are advanced impulse heat and quantity settings through HMI, and jumbo film roll handling facility forincreased productivity.

The Filpack Servo SMD can be used to pack edible oils, ghee, vanaspati and a variety of viscous products such as mango pulp, tomato puree, fresh cream, shrikhand and mayonnaise. This machine has been successfully installed and is in regular production at many of the leading oil manufacturers such as Kallesuwari, Cargill India, Wilmar Group, Liberty Oil Mills, MK Agrotech, Nataraj Oil Mills, Kamani Oil Industries, PGEO Edible Oils, Swastik Oils, Narayani Oils and Kanpur Edible. “The Indian consumer is getting more and more aware about the quality and safety and that is the reason for sales growth of hygienically packed oil pouches. With the growing markets, manufacturers demand low footprint and lower cost of ownership for the packaging machines. The Filpack Servo SMD machine fits this bill,” says Mrunal Joshi, executive director of Nichrome.

Integrated project solution

Nichrome offers integrated project solutions for handling and packing of oil with over 5,000 installations in 40 countries worldwide. Along with its vertical form fill sealing machine (VFFS) range for solids, liquids and powders, Nichrome also offers VFFS multilane technology in technical collaboration with Prodo Pak, USA and horizontal form fill seal (HFFS) packaging machines intechnical collaboration with Totpack, Spain for dairy, food, cosmetics, pharma and chemicals.