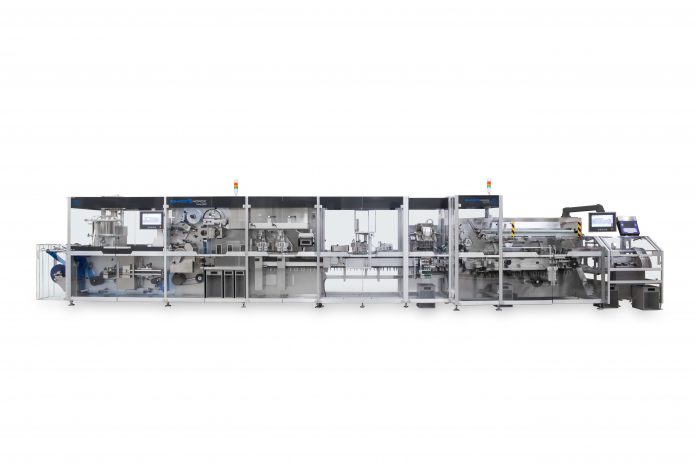

The new Unity 600 blister packaging line from Romaco Noack is a high-speed machine for medium to large batch sizes. This monobloc transfer solution was specially designed for blister formats arranged crosswise to the running direction. Compact, carbon-neutral, and digital – the Romaco Noack Unity 600 blister packaging line is a monobloc transfer solution that was specifically designed for blister formats arranged crosswise to the running direction. With a maximum output of 600 blisters and 400 cartons in a minute, the Unity 600 is a high-speed machine for medium to large batch sizes. It is an ultra-compact line that impresses with a very small footprint, especially in the cleanroom for the primary packaging. The modular system concept consists of a blister machine with rotary sealing and a continuous motion cartoner. If required, the Unity 600 can be combined with different cartoners, track and trace systems, and final packaging solutions from Romaco. The Premium line of the Noack 950 product family can be configured with various feeding units and is extremely flexible in every respect. Reproducible…

Choose your subscription to read more

Trial

- ₹ 0 for 4 weeks*

PSA Plan 1

- ₹1,500.00 for 1 year*

PSA Plan 2

- ₹2000 for Year*

PSA Plan 3

- ₹3,600.00 for 2 year*