In response to growing concerns over the environmental impact of food packaging, Japanese companies are taking innovative steps to cut emissions without compromising quality. A new collaboration between Don Quijote (Pan Pacific International Holdings Corporation), Sagawa Printing and Asahi Kasei—parent company of Asahi Photoproducts—has led to a significant reduction in CO2 emissions in the printing of frozen pasta packaging.

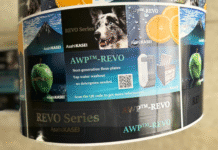

For the private-label ‘Yaba Mori Pasta’ series, Don Quijote has chosen to implement water-based flexographic printing, using Asahi’s AWP water-washable flexographic plate. This printing method replaces conventional solvent-based gravure printing, a dominant practice in Japan, and marks a forward-thinking step in sustainable food packaging.

Sagawa Printing established the optimal printing conditions for this transition in close collaboration with Asahi Kasei. According to their calculations, this method is expected to reduce CO₂ emissions from the printing process by approximately 60 percent compared to conventional gravure systems.

Water-based flexographic printing inherently generates fewer emissions, thanks to the water-based inks and the AWP plate’s development process.

While solvent-based gravure printing continues to dominate Japan’s packaging industry, growing environmental awareness is driving interest in more sustainable alternatives. The ‘Yaba Mori Pasta’ packaging serves as a tangible example of how food brands can reduce their environmental footprint through innovation in print technology.

Through partnerships like this, Asahi aims to contribute to a more sustainable society, promoting the elimination of VOCs and supporting cleaner production processes across the food packaging sector.

Sustainable shif

Asahi’s AWP (Asahi Water-Washable Plate) represents an innovative approach to flexographic platemaking, replacing traditional solvent-based processes with water-based solutions. This advanced technology eliminates the need for organic solvents during plate development, significantly reducing volatile organic compound (VOC) emissions and improving safety and environmental performance at printing sites. Moreover, AWP plates enhance print consistency, improve productivity, and deliver exceptional print quality, making them particularly suitable for high-standard food packaging applications.

The adoption of AWP technology is central to Asahi’s broader Solvent ZERO initiative, aimed at helping the packaging and printing industries transition away from solvent-based systems towards fully sustainable production methods. Through Solvent ZERO, Asahi encourages printers worldwide to adopt water-based flexographic systems, promoting cleaner air, safer working environments, and substantial reductions in carbon footprints. The ‘Yaba Mori Pasta’ packaging project clearly demonstrates the practical benefits of embracing such advanced flexographic solutions, highlighting measurable sustainability gains without compromising print quality or operational efficiency.

By driving industry-wide adoption of its Solvent ZERO principles, Asahi actively supports global sustainability goals and the growing demand for environmentally responsible packaging solutions.