3D printing is an additive process. It is used to create three dimensional solid objects from a digital CAD file. Using an additive process, many if not most 3D printers use fused deposition modelling (FDM). Essentially these are similar to inkjet printers used for proofing and printing but instead of inks creating an image on a flat substrate, objects are made by jetting successive layers of materials. This is not a new process in India as many machine and engineering component manufacturers have been creating scaled prototypes by jetting materials that resemble a mixture of colored sawdust and adhesive. However, distinct from other or earlier 3D printers, FDM printers use real industrial thermoplastics.

3D printing is also known as additive manufacturing and in economies with highly developed engineering industries, the discussion has already begun on series manufacturing of objects or components using this technology. Of course the implication is that these may be objects or machine parts that have very complex shapes or that needed in relatively short runs but in either case it would not be necessary to create a pattern for a casting and then to machine and polish these to close tolerances. 3D systems are already available for a variety of tolerances and for jetting a range of materials (industrial thermoplastics) for applications ranging from machine parts to FDA approved pharmaceutical packaging and even medical applications. Colored and transparent materials are also available.

There is no question that with the wide availability of three-dimensional design software these printers can play an enormous role in India where manufacturing is often made possible by jugad but generally means the spread of a culture of cutting corners and making do and not producing any product with precision, repeatability or excellence. Too often we praise ‘jugad’ because we are unable to manufacture a part or component to a correct tolerance. In fact a huge role in any manufacturing activity is that of innovative tool design and tool making. The ‘Make in India’ campaign can never succeed if we do not become innovative tool and machine designers. Without this capability and elevation of our ingenuity, we cannot even become efficient users of the best imported machines.

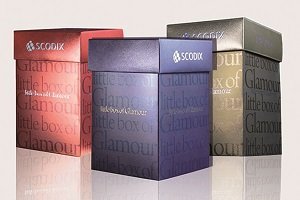

Thus 3D printing offers huge opportunities in all spheres. 3D enhancement of print is already a huge success in the country. The installed base of Scodix print enhancement machines used for the decoration of printed photo books and other applications is already more than 15 machines and probably closer to 20 in India. This installed base for the new technology Scodix machines is second only to that of the US. Just as digital print of short run high value photo books has turned out to be a huge market in the country, 3D print decoration is a must-have value-add and it is a matter of time before it is also used to prototype all kinds of textures and embossing on packaging prototypes and short run product and design testing.

The technology is capable of producing hollow objects to reduce the density or weight of certain objects or components. It is likely that the next and imminent step is of course to design and produce 3D packaging prototypes of let’s say an innovative plastic shampoo bottle or perhaps a rigid plastic container that will ultimately be shrink wrapped. Innovations in caps and closures can also be easily designed, prototyped and tested. This is where the industrial thermoplastics can play a role together with those that are FDA approved.

The technology is capable of producing hollow objects to reduce the density or weight of certain objects or components. It is likely that the next and imminent step is of course to design and produce 3D packaging prototypes of let’s say an innovative plastic shampoo bottle or perhaps a rigid plastic container that will ultimately be shrink wrapped. Innovations in caps and closures can also be easily designed, prototyped and tested. This is where the industrial thermoplastics can play a role together with those that are FDA approved.

In a recent article in the national press reporting on a research study, the Indian 3D printer market was projected with a value US$ 79 million (approximately `500 crore) by 2021. Assuming that this is the cumulative value of 3D printers and systems that are expected to be absorbed by the Indian market, it is likely that the majority of these printers are likely to based on FDM technology and used for design, prototyping and 3D modelling in various industries from automotive, medical and aerospace. The technology is already widely used in developed markets for health applications including dentistry.