For over 50 years, the classic EAN/UPC barcode has powered the global retail and logistics ecosystem. But as industries move toward digitalization, transparency, and sustainability, the familiar black-and-white stripes can no longer carry the growing amount of information demanded by regulators, retailers, and consumers alike.

That’s why the future belongs to 2D codes. Under the GS1 standard, several symbologies — GS1 DataMatrix, GS1 QR Code, and GS1 DotCode — are now officially recognized for product identification. These formats can store far more data than a linear barcode while remaining compact and scannable at high speed.

To ensure global interoperability, GS1 compliance is key. It guarantees that every encoded element — such as the Global Trade Item Number (GTIN), batch, expiry date, or serial number — follows standardized application identifiers that can be read by any GS1-capable scanner worldwide. Only codes created according to these rules qualify as GS1 2D codes, ensuring consistency across industries and countries.

The next step: GS1 digital link

Building on this foundation, GS1 Digital Link takes the next step: it transforms these compliant 2D codes into web-enabled gateways. By embedding the same GS1 identifiers into a URL structure, each product becomes part of the internet — a bridge between physical packaging and digital data.

From a simple stripe to a universe of data

Unlike the one-dimensional barcode, which holds just one number, the GS1 Digital Link contains structured data and a network address. It can be scanned by warehouse systems, retail scanners, or smartphones — and deliver context-specific information every time.

That means one single 2D code can identify a product, provide traceability data, and connect to a webpage or database containing details about ingredients, origin, or recycling. One code, many functions.

Unlocking real value along the supply chain

The practical benefits are substantial:

Product safety: Recalls become more precise and cost-effective, targeting only specific batches instead of entire product lines.

Transparency for consumers: A quick scan reveals where a product comes from, what it contains, and how it should be recycled — no extra app required. (It is important to note that not all mobile phones can currently scan these codes, but this will change in the near future.)

Marketing and engagement: Brands can use the same code to launch campaigns, recipes, or loyalty programs, turning packaging into an interactive experience.

Data integration: Manufacturers, logistics partners, and retailers exchange real-time data automatically, improving supply-chain responsiveness and visibility.

The GS1 Digital Link not only makes traceability smarter but also opens a new world of connected packaging and consumer trust.

What manufacturers should watch out for

With more data comes more responsibility. The readability of a 2D code depends on precise printing, contrast, and positioning — especially on challenging substrates such as flexible film or metalized surfaces. The right ink, droplet size, and layout are critical to achieve reliable GS1-compliant results.

Manufacturers must also ensure data flexibility. Information such as batch numbers and expiry dates is constantly changing and must be sensibly integrated into print jobs for the printer. In addition, many retail scanners are still transitioning to full 2D-readiness, so collaboration between manufacturers and trading partners is essential.

Finally, maintaining accuracy over time requires a solid data-management backend. Content may evolve, but the GS1 Digital Link ensures that the printed code always points to the right, updated information.

The GS1 Digital Link — together with GS1 DataMatrix, GS1 QR Code, and GS1 DotCode standards — marks the beginning of a smarter era in product identification. It connects the physical and digital worlds, transforming packaging into a dynamic source of information.

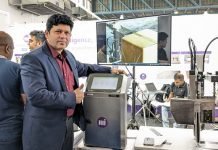

With LEIBINGER’s precision printing systems, manufacturers can achieve the reliability, flexibility, and GS1 compliance needed for this transformation — ensuring every code is sharp, readable, and future-proof.