Proseal, a provider of tray sealing technology for the food industry, has developed an ultra-hygienic conveyor to help food manufacturers meet food quality and safety standards.

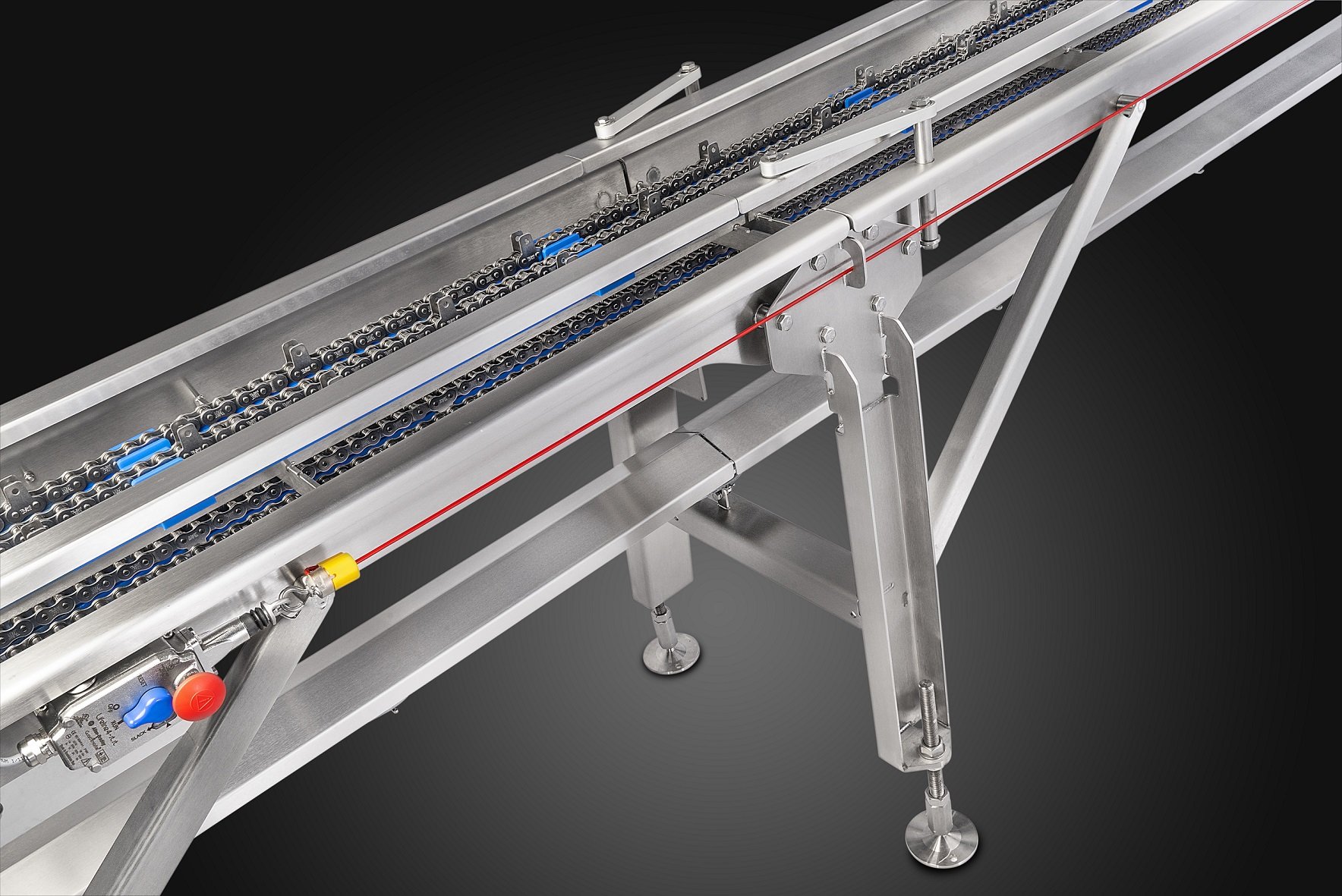

The OC Conveyor has a number of unique features to avoid potential food traps, together with an enhanced design that ensures fast and thorough cleaning during wash-down. The new fully folded construction of the conveyor has removed any box sections or tubing. These are areas where food can sometimes get trapped. In particular, sealed tubes have the potential for bacteria to develop if the integrity of the tube is breached in any way, for example through a small hole or crack in the weld since the inside of the tube cannot be cleaned.

Similarly, open wiring looms have replaced the more common wire bundles, removing another potential food clogging and providing easier access for the cleaning of individual cables. A further significant feature is a replacement of moving belts with a new wash-through chain transport system. It speeds up cleaning and eliminates belt maintenance costs.

The latest version of Proseal’s OC Conveyor retains all its existing benefits, including a modular design that allows customers to specify length, width and tray pitch for precise integration into the production line. It is capable of sealing up to 60 packs per minute in single lane configuration and 120 packs per minute in twin lane, providing the ideal complement to Proseal’s GT range of tray sealing machines and their various speeds as part of a fully automated line. A user-friendly, menu-driven control panel ensures ease of operation and fast set-up and changeovers.

The introduction of the new model reflects the trend towards increasingly stringent legislation and retailer standards in terms of food quality and safety, as well as more demanding consumer expectations. “Hygiene has always been a critical part of our equipment design, and we are always seeking ways to develop this further. The conveyor is a vital but sometimes overlooked part of the food packing line. By further enhancing the design of our OC Conveyor, we are providing manufacturers with the reassurance and peace of mind of a fully integrated tray sealing solution that enables them to deliver the consistently high-quality foods that consumers expect,” explains Rob Hargreaves, director, Proseal.