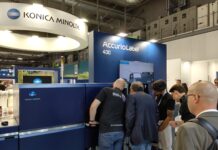

Baldwin Technology will showcase its latest high-performance color management, surface treatment, LED-UV curing, inspection, defect detection and Industry 4.0-based analytics solutions at Print4All in pavilion 9, stand G15 H16, which is taking place May 3-6 at Fiera Milano in Italy.

Printers are under unprecedented commercial pressures because of paper shortages and energy costs. Technologies that help printers and converters minimize paper, ink, time and energy waste have never been more in demand. Simultaneously, the need for flawless, sustainable printed products drives the industry to technologies that support outstanding results. Plus, the burgeoning demand for flexible packaging and labels has put pressure on printers and converters to produce them at the highest quality and the fastest possible speeds.

Customers seeking solutions are gravitating to Baldwin and its LED-UV curing technology. One of its latest advances—which will be on display at Print4All—is the XP Quatro Series LED-UV curing module with one head and two frequencies for broader applications. It is designed to economically and efficiently cure LED-formulated printing inks and coatings on sheetfed and web offset printing presses, as well as on larger-format flexo presses and digital print engines. The XP quatro series LED-UV enhances print quality while operating at top speeds, driving increased productivity and profitability.

Italy’s ACM flexible packaging selected Baldwin as its LED-UV partner and became the first flexible film converter to offer all LED-UV curing in a narrow to mid-web format. This partnership established LED-UV printing as a growing production standard in flexible packaging and labels. Today, ACM is a 100% LED-UV, non-mercury facility.

“Together with Baldwin’s technology, we proved that LED-UV could dramatically improve the printing process and make narrow web food-grade cured packaging a reality,” said Antonio La Franceschina, co-founder of ACM. “With LED-UV, we can ensure rapid and uniform drying, so we are able to reduce production cycle timing and more quickly satisfy all customer requests.”

Baldwin’s Print4All booth also will showcase Industry 4.0 and industrial Internet of Things-enabled technologies that work together to achieve greater uptime, productivity and automation. Featured solutions pair sensor-gathered data with operational data from Baldwin equipment to gain live, actionable insights to improve production monitoring, so printers and converters can achieve new levels of color consistency with fewer defects and greater assurance of curing. On May 3 at 3 pm at Arena Jobs-pavilion 9, show attendees can learn more about the advantages of Industry 4.0 during “Sell more, more profitably with IIoT,” a presentation hosted by Simon Blake, chief marketing officer at Baldwin.

“Data will drive the next great advantage of the graphics industry,” said Steve Metcalf, chief IoT officer at Baldwin. “Shorter print runs and more customization are just two challenges facing the industry and testing efficiency. Comprehensive, connected data—from inspection to color to curing—will give everyone the information needed to make decisions to sell more print, profitably.”

Other highlights in Baldwin’s stand include the Corona Slim treatment system, which ensures the exact dyne levels needed for perfect uniformity in the application, and the Guardian PQV 100% Print Inspection, which provides complete print quality verification from prepress through production, reporting and archiving.