The Innopal PLR has complemented the KHS GmbH product portfolio since 2022. The Dortmund systems provider has now readied the high-performance palletizer for serial production – with targeted further developments and positive customer feedback.

For KHS, the market launch of the Innopal PLR marked a significant milestone, as Ralf Kretschmann, product manager for palletizing technology at KHS GmbH, emphasizes, “The Innopal PLR is a new phenomenon and figurehead for KHS palletizing technology. It caters to the high-capacity range, combines this with a low-level infeed, and with its robotics, it’s also highly automated.” This smart system thus gives users a number of benefits, particularly regarding efficiency and automation, plus work safety and ease of operation.

KHS: many years of expertise in palletizing and robotics

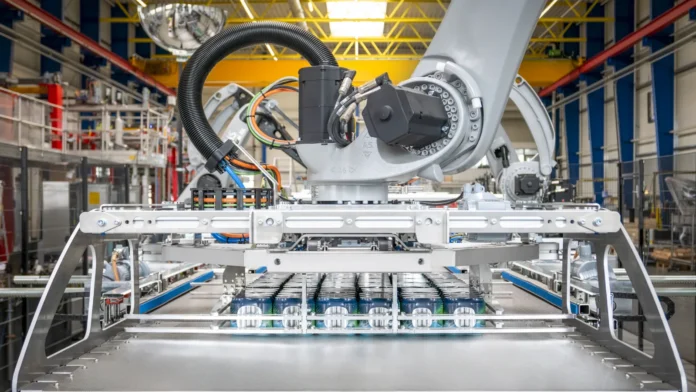

The Innopal PLR specifically serves the high global demand for robot systems in palletizing. “These were and still are predominantly configured for the low-capacity range,” explains Kretschmann. With the Innopal PLR, KHS has consciously taken a different approach. With its latest robot generation that has a throughput of up to 650 layers per hour for PET bottles and cans, it’s perfectly designed for customers who want high performance in this field. Line capacities of up to 240,000 containers per hour can now be achieved by a single palletizer with high stacking accuracy.

The palletizer grouping system is equipped with the new InnoPET iflex option that enables fully automated format changeovers. This technology also permits the gentle processing of various sustainable packaging systems such as PaperPack, KHS NMP (Nature MultiPack), and trays without film. This high degree of automation has a positive impact on the efficiency, safety, and speed of format changeovers. It also eases the operator’s workload.