Gujarat Print Pack, a BRC and ISO-certified firm with expertise in manufacturing pressure-sensitive labels, shrink sleeves, mono cartons, and shipper boxes, has installed anilox rollers from Apex International to keep up with the dynamics of the label converting industry.

The Ahmedabad-headquartered company has a wide variety of packaging products, and pressure-sensitive labels have always played a pivotal role in the industry. The company feels the Indian label industry is a highly competitive market space and thus requires a great deal of creativity to ensure that your organization stands out among others. These dynamics of the Indian label industry have kept label converters on their feet and a continuous learning path.

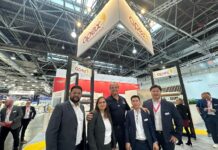

Gujarat Print Pack started using Apex anilox rollers three years ago and is happy with both the company and its products. Director Shail Patel said, “Since then, we have started converting all of our manufacturing locations as well as anilox to GTT. We count many leading national and international brands among our customers with a focus on food, beverages, cosmetics, and other FMCG categories. We have three strategic manufacturing locations — our mother plant in Mehsana, Gujarat, is an industry 4.0 manufacturing site with BRC certification. It can manufacture all of our products to the maximum of our abilities. Our other manufacturing plants in Ankleshwar in Gujarat and Nairobi in Kenya are much more specialized and targeted towards specific industry segments,” Patel said.

Patel said they chose Apex due to their reputation for quality and consistency. “We conducted a few trials with their GTT anilox and were pleased with the performance. Having used them over a longer period, we can attest to the longevity and consistency of the performance. GTT anilox allows for a much higher production speed without the problem of ink spitting. Their anilox is much less prone to cell filling. The consistency of ink laydown is also significantly better as compared to a hexagonal anilox. All of these properties align very well to ensure proper ink and color management across multiple printing machines and different locations.”

One of the biggest challenges used to be matching colors across all printing machines and locations. Apex’s anilox has a high level of consistency in engraving, which ensures that if properly maintained, the same color is achieved regardless of the printing machine.

On the role of labels at a time when brands are trying to reduce their packaging, Patel said so far many organizations have reduced or removed tertiary corrugated boxes, followed by mono cartons. “What’s next? We are already seeing more and more packaging material getting direct printing with silkscreen, digital and other processes. This revolution is firmly in process for tubes and may well take away the pressure-sensitive labels market in other areas as well. Till then, improved labels remain a convenient and economical means to remove secondary packaging while still conveying the information to consumers.”

According to Patel, sustainability should be a concern for everyone, not just governments and organizations. To leave the earth habitable for future generations will require cohesive efforts from this generation, he said.

On expansion plans, he said, “We have added one manufacturing location in each of the last two years. We hope to keep this momentum, and add new focused manufacturing locations across different regions.”