In the past few years, as we have been learning about flexible laminates and packaging, we have seen a range of imported and Indian manufactured co-extrusion laminators and blown film lines. A visit to the Rajoo factory and its nearby R&D center reveals why the company has become a globally competitive manufacturer and exporter of blown film lines and why it is likely to be very successful with the jointly developed with Kohli, Lamex co-extrusion laminator and coater.

At the Rajoo factory, expertise in die-design is leveraged with a top-notch engineering design department. The manufacturing of extrusion dies with absolute precision is performed on the latest automated machining centers. This is key since the performance of a die is binary – it either works as specified or it doesn’t. Any flaw can be a lifelong drag on the quality of film extrusion and it is the quality of the extrusion die and its ease of maintenance that are often foremost in the choice of a blown film line.

Rajoo Innovation Centre

Within walking distance of the Rajoo factory where it manufactures its blown film lines, its thermoforming tray manufacturing machine and the new Lamex coextrusion laminator, the company runs an innovation center with a material testing lab and a running 7-layer blown films line and other production equipment. The purpose is to try and test various combinations of polymers to produce new film laminates.

The Rajoo Innovation facility is used for testing and training and often by consumer product companies to come up with more effective or even sustainable films. On the day that we visited it, a trial for a global masterbatch and additive supplier had just taken place on the 7-layer blown film line.

Rajoo also uses this blown film as a back-up for its customers. In case any of their customer’s lines are down for any reason, the Innovation center can make the film needed to maintain supplies.

The last point is that the family-owned Rajoo Engineers is run on a day to day basis by its highly educated next generation in a hands-on manner. Khushboo Doshi is a trained architect and product designer who has topped up her qualifications with an IIM course on family business transition. We met her briefly on a busy day of showing customers the new coextrusion laminator. At the same time, she was finalizing customer orders.

Product and industrial design

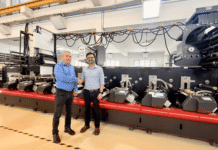

Several features of the plant architecture and design attest to modern and creative ideas of movement and detail in the workspaces that are influenced by Doshi. Moreover, the new Lamex coextrusion laminator is an excellent and functional example of industrial equipment design.

It is neither boxlike nor very bulky but looks modular. In the areas where the material moves the machine appears trim and streamlined and where the actual co-extrusion and other functional aspects require it, the modular side frames that protrude have curved red covers while the ancillary components move out to a boundary. Apart from being a good looking machine, its technology and control areas seem to have good operational access and ergonomics. We believe that similar attention has been paid to the maintenance access as well.