Package printing will be a core area at Labelexpo Europe 2015 in Brussels. Set to be the biggest ever in its 35-year history, Labelexpo’s show floor and feature areas will put the spotlight on the lucrative commercial opportunities package print production offers. Lisa Milburn, managing director of the Labelexpo Global Series, says, “Package printing is now central to the label printing community and Labelexpo experience. With 53% of our total exhibitors showing products for flexible packaging and 32% featuring products for folding cartons, Labelexpo Europe offers all printers the most extensive showcase of package printing solutions available. Nowhere else will print industry professionals find such a comprehensive range of suppliers and technologies which will help gear up their business, improve profitability and add value for their customers.”

Package printing will be a core area at Labelexpo Europe 2015 in Brussels. Set to be the biggest ever in its 35-year history, Labelexpo’s show floor and feature areas will put the spotlight on the lucrative commercial opportunities package print production offers. Lisa Milburn, managing director of the Labelexpo Global Series, says, “Package printing is now central to the label printing community and Labelexpo experience. With 53% of our total exhibitors showing products for flexible packaging and 32% featuring products for folding cartons, Labelexpo Europe offers all printers the most extensive showcase of package printing solutions available. Nowhere else will print industry professionals find such a comprehensive range of suppliers and technologies which will help gear up their business, improve profitability and add value for their customers.”

Taking place from 29 September to 2 October, the show is aimed at trade professionals including label and package printers, brand owners and designers. Visitors to the expo will be able to see and source the latestlabel and package printing solutions from over 600 exhibitors including several companies such as Convertech, Domino Digital Printing Solutions, Gallus, Multitec, Monotech Nilpeter, Sun Chemical, Soma Engineering, and more.

BST eltromat Stand 6C46/6C58

At Labelexpo Europe, BST eltromat International will focus on the areas of 100% inspect- ion, workflow ,web monitoring and color measurement and web guide regulation. Ingo Ellerbrock, product manager, BST eltromat, says, “The trend in label printing is increasingly going in the direction of standardized, extendable compact solutions. At Labelexpo we will present our cost saving entry level solution for web guide regulation with EcoGuide amongst others. Moreover, we are combining a wide array sensorfromour subsidiary Accu Web, USA withourtried and tested controller ekr 500 digital for the first time. These wide array sensors have large measurement areas to electronically compensate for changes in the web width, and therefore make mechanical adjustments and or manual alignments of the sensors superfluous.”

Apart from the latest developments in web guide regulation, the tried and tested BST eltromat systems CompactGuide and SmartGuide, the digital sensor CLS Pro 600 and the current ekr controller generation will also be displayed. Moreover, BST eltromat is showing its innovative solution for the measurement of absolute color values with the iPQ-Spectral. In addition, a further process sequence will be introduced, which was developed in cooperation with coe.

Dirk Volkening, product manager, BST eltromat, says, “iPQ-Check,the module of the iPQ-Center for the 100% print image inspection, now has new, self-developed high performance LED lighting. This means that the module is suitable for printing flexible packaging, opaque (lightproof) and reflective materials and normal paper.”

BST eltromat will also be showcasing one ofthe most economic models for video web monitoring – thePowerScope 4000. The operation ofthe system primarily conceived forlabel printing and other narrow web applications, is now even more userfriendly

Convertech Equipment Stand 4E20

Equipment. Photo PSA

Convertech Equipment, an Indian manufacturer of doctor blades, will launch at Stand 4E20 theSureprintExcelPro range at LabelexpoEurope 2015,whichis said to make it possible to achieve lowfrictiondoctoringwithlongerrunning life.Sureprint is the brand name under which Convertech Equipment exports its doctor blades to several countries. Manufactured under ISO 9001:2008 certification, these doctor blades are available in many varieties and edge configurations. The superior characteristics of these blades eliminate issues of faster wear and tear when using metallic printing inks.

Started in 1993 and now in its second generation, Convertech has seen a lot of changes over the years and witnessed the Indian print industry evolve over the years. While speaking to Packaging South Asia, Rahul Sanon and Dhruv Sanon of Convertech Equipment said thatthe company nowoffers smart solutions to its customers.

OtherproductsConvertechEquipmentwillbe showingatits standinHall 4will include Sureprint HST and Sureprint Excel doctor blades for standard flexo and gravure printing applications as well as for coating applications. The company has been a regular participant at Labelexpo Europe since 2009.

Domino Digital Printing Solutions Stand 9A60

The Domino stand will feature the high productivity 7-color N610i, not only as a standalone roll-to-roll label press, but also as a modular hybrid solution integrated withanABGDigicon3 incorporatingflexo, varnishinganddiecuttingmodules. Also to be featured on the stand are two K600i digital print modules, which will be integrated onto a GraphiMecc web inspection system to print black variable data and present Domino’s new digital foiling solution. The solution uses the K600ito print a digital adhesive and create the image area priorto UV-curing and delamination.

Gallus Stand 5B28/5C31

With the Labelexpo Europe around the corner,the mood is quite optimistic at Gallus. The company is going to launch at Stand 5B28/5C31 the DCS 340 – its new digital press which was also shown during the Gallus Innovation Days 2014.Galluswill also be showing a new improved version of its popular ECS with UV technology. Moreover, an improved model of its RCS will be shown at the show.

Goss International Stand 7D18

addition to the Goss Sunday Vpak press series, will be a highlight for visitors to the Goss stand

At Labelexpo Europe 2015, which will be held from 29 September to 2 October, Goss Internationalwill be presenting its latest offsettechnology developments and opportunities for converters at Stand 7D18 at Brussels Expo, Place de Belgique. First-hand information aboutAlwan’sColor Expertise Technology, a recent addition to the Goss Sunday Vpak press series, will be a highlight for visitors to the Goss stand. This latest suite of software is nowcommercially available following months of rigorous testing at Goss’s Packaging Technology Centre, Durham, New Hampshire (USA).

Alwan’s technology suite features an extended color gamut, which adds two or three inks to conventional process inks, enabling exact brand color reproduction without the need for spot inks. Facilitating a substantialreduction in the costs usually associated with ink change overs, the update is expected to bring customers a 30 to 50% costreduction compared to the use of spotinks through a combination of eliminating ink changeovers and reduced ink inventories.

The extended color gamut is just one feature on the four-part technology suite from Alwan which is now available on the fullGoss productrange. The suite also includes color manage- ment and quality control software which helps to increase print quality and consistency; reduce cost and ultimately maximize productivity across the production cycle. Goss has also made a number of highly anticipated changes to its Vpak presses in ordert o further reduce waste and optimize the printing process for flexible packaging customers in particular.

AccordingtoGoss,thepartnershipandtechnologyupdates reflectthe company’s commitment to driving ongoing development across their portfolio, and follow a number ofrecent‘kaizen’ eventsheld specifically to improve equipment designand streamline processes. “With the growing trend towards shorter run lengths, printers and converters are increasinglyhaving to find solutions to balance customer expectations and profitability,” continues Muncaster. “Our mostrecent ‘kaizen’ event focussed on job changeover process which is now increasi- ngly critical in order to make customers’ working lives easier and more profitable. We are extremely excited to share our latest developments at Labelexpo this year, anddemonstrate how our people, products and partners are together delivering the flexibility, highquality and cost effectiveness that is so essential in today’s packaging market.”

IGT Testing Systems Stand 11F42

number of pre-programmed test methods and the possibility to add customized or complete new test

methods by a customer

IGT TestingSystems,the world’s leading manufacturer of printability testers, has launched a new version of its printability tester for flexo inks – the IGT F1. The new IGT F1 allows inkmanufacturers, printers and suppliers offlexiblematerials tomeet their high quality standards by ensuring consistent testresults in both production and R&D environments. The IGT F1 is a well established testing system in the flexo and gravure ink and printing markets. IGT is exhibiting it at Labelexpo Europe 2015 from 29Septemberto 2 Octoberin theParc des Expositions in Brussels, Belgium at Stand 11F42, Hall 11.

The IGT F1 includes a complete PC inside for control and storage of data and settings for each test and a number of pre-programmed test methods with the possibility to add customized or complete new test methods by a customer. The settings can also be exported to an Excel file for later analysis, or can be printed on a label printer to mark the printed strips before filing.

Industrial Inkjet Stand C70 Hall 9

IndustrialInkjet(IIJ)willbe launchinganew600dpihigh-speedmono range at Labelexpo 2015. With print widths up to 520 mm, the industrial inkjet pioneer says these new models are suited to printing of variable text down to 2 pointfonts at over 50 metres a minute.

IIJ provides a wide range of inkjet modules ready forinstallation onto customers’ existing flexo label presses,for exampleNilpeter,MarkAndy andGallus.Combining inkjet as a module onto a flexo press provides a flexible, reliable and economic alternative to standalone inkjet label presses. Powered by Konica Minolta’s inkjet technology, the company says the modules offer high uptime and the longest printhead life in the industry.

Followingthe successful launchofits iSrange ofhighquality colorinkjetmodules in 2014, IIJ has been busy working on its monochrome range. These units print full variable images in black, white, varnish or spot colors, as well as security inks such as IR black or UV-fluorescent. In early 2015 IIJ launched its new HS or high-speed models that print high resolution continuously variable textimages andbarcodes at a sustained speed in excess of 160 metres a minute. Now IIJ is extending its mono offering to include 600 dpi native resolution. IIJ tests and approves inks from a wide range of ink suppliers, both UV and water-based, which ensures that the optimum ink is available for every customer’s specific application.

John Corrall, managing director and founder of IIJ, says, “Compared to standalone units, our modules provide the lowest cost of ownership, estimated at between 30 and 60% lower than competitors. Combined with a wide choice of inks, from process color to special effect and invisible security inks, they offer the best break-even point when compared with the cost of flexo print. With over 150 production lines running across the world, IIJ’s range of ColourPrint and MonoPrint inkjet modules are a proven cost-effective solution, as our customers testify.”

Mark Andy Stand C45

At Labelexpo Europe 2015, Mark Andy will showcase a comprehensive range of business responsive technologies – innovative solutions designed to respond to your business needs. Some of the innovations that will be on display include a hybrid inkjet and flexo printing platform, which is flexible and configurable. The company will showcase a servo-driven entry-level machine compatible with almost any plate tooling and outfitted with Mark Andy ProLED UV-LED curing system and QCDC technology. With the Mark Andy Performance Series P7 you can experience high quality extended gamut printing on the most advanced model in the Performance Series line. At the stand you can learn about new advancements in offline finishing including ReportManagementSystem(RMS), a key feature on the exclusive URC2.0 control system, available on the high-speed, servo-driven RotoflexVSI and VLI.

Max Speciality Films Stand 11D48

The Indianmanufacturer,MaxSpeciality Films,willbe exhibitingat LabelexpoEurope 2015 forthe firsttime.AtStand11D48 the companywillbe launchingthreenew ranges including IML films – claimed to exhibit consistent flatness, high gloss, mechanical stability andresistance to mechanical, thermal and chemical exposure. They will print with offset, gravure, flexo and digital processes, and are also availablewith ‘OrangePeel’ effect. The companywill also showa range of pressure-sensitive films that include white cavitated, clear or metallized – suitable for a range of applications including on contoured and squeezable containers.

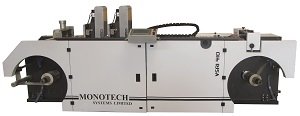

Monotech Systems Stand 9A58

At Labelexpo Europe 2015, Monotech Systems will be highlighting its JETSCI range of products thatincludes industrial inkjet systems, slitter-rewinders, label inspection system and brand protectionsolutions.Monotechwillhave aninformation booth atits stand to discuss aboutits innovations made in India. Recently the company has announced its association with Focus Labels for bringing the conventional flexo presses to the Indian market. Focus Labels will be displaying its Eflex flexo press at their stand and will also be launching the Proflex flexo cum digital press at the expo.

Monotech has already launched the JETSCI VSRI in India and will have installations as well. This time it will be highlighting this product at Labelexpo Brussels in additionto the announ- cement andlaunches fromitspartner Focus.The company is also working on a few interesting projects for the labels and packaging industry which will be again a different innovation. Apart from this, it is also working on delivery of the orders that it has received. Monotech has already exceeded 30 installations worldwide.

Multitec Stand 5C22

Multitec will be showcasing its Ecoflex 8-color VSi flexo press at Labelexpo Europe 2015. Amit Ahuja, director of Multitec informs Packaging South Asia that the press has been upgraded and improved with several modifications that will be showcased. Multitec is expecting to do well in new markets in Europe and Africa with the Ecoflex VSi model and is hopeful that Labelexpo Brussels can help swing some deals. It is expecting to close at least two or three deals at the show and expects to clinch a few orders afterthe show.

Ahuja says, “Multitecwith rising domestic and export sales has moved sufficiently ahead ofits Indian competitors to become the marketleader.We have a large and growing market in India and in times to come the letterpresses and the secondhand machines will become obsolete and disappear. We hope to continue to hold a fifth of the market share, despite the competition.”

Nilpeter Stand 7B35

Apart from the bigger, faster and better versions of its regular flexo presses, Nilpeteris going to show a complete digital label press forthe first time at Labelexpo Europe 2015. The press combines Nilpeter’s expertise in web handling with advanced inkjet technology based on Screen’s digital print system and workflow. Nilpeter has adapted several of its in-line finishing modules for digital production which include a web in-feed, varnishing unit,the innovative QC-Diecutting system, smartmatrix stripping, lengthslitting, varnishingunit andsmallrolldualrewinds.A mark sensor allows the precise reinserting of webs for reverse printing, or overprinting of preprinted webs, including variable data – readily usable technology for the customer. Moreover, the FA 4 flexo press will be shown at the show.

SMI Coated Products Stand 11A27

SMI is going to participate at Labelexpo forthe third time. Rohit Mehta, corporate director atSMI says, “Every Labelexpo Europe is a great opportunity to meet prominentplayers from across theworld. Labelexpo Europe is always a verybusy showfor us.At the show, SMI is going to display its wide range of labelstock solutions that it offers for various label applications. SMI will be focussing more on films this year. We will be showcasing our filmic labelstock solutions and also numerous labelstock solutions using filmic liner.”

“SMI keeps on investing as per market needs. We expect this yearto continue be an opportunity to foster growth. The industry has a great scope of growth in India as well as across the world. There was a time that growth was a matter of concern, today is a great opportunity to caterto this growth. New markets and applications are constantly emerging,” adds Mehta.

SPGPrints Stand 8A10

2015

SPGPrints has extended its range of RotaPlate reusable nickelrotary screens, by introducing two new screens for creating eye-catching varnish effects on self-adhesive labels. These screenswillmake their global début at Labelexpo Europe 2015. RotaPlate 75Q applies deposits of approximately 100 µm thickness. The screen ensures a finely balanced proportion of emulsion over mesh, approaching zero, so that solids and fine details can be reproduced with identical results. Moreover, RotaPlate 125V prints subtle patterns of 26 µm thickness, forfine linework and text. The screens are suitable for a host of added-value packaging applications, particularly in the beverage sector. The tactile image, created by printing a clear varnish over an existingimage, is aneffectiveway of addingvividness to aniconorbrandname, and thus enhancing retail shelf-impact. Using rotary screens to apply varnish offers a waste-free alternative to the embossing technique.

Available onrollsup to 565mm(22.2 inches)wide, RotaPlate comes as a pre-coated, non-woven mesh that is assembled into a cylinder. It features the acclaimed welded nickel hexagonal hole-formation thatis standard in allSPGscreen technology. The high strength ofthis constructionenables screenreuse and print speeds of up to 50 metres a minute (164 fpm). RotaPlate is an economical solution for achievinghigh-quality results and stability atrelatively fast print speeds.It offers excellent performance on all leading rotary screen presses and modules. The Rotaplate range comprises six screens, which collectively provide a solution for printing tactile effects from fine lines to Braille, in thicknesses from 26 µm to 250 µm.

Soma Engineering Stand B39

At the show, Soma Engineering will display at Stand B39 its mid-web Optima CI press – a new platform in flexographic printing presses for the label and package printing industry. Known as a wide web flexo press manufacturer, Soma has developed the Optima as a mid-web CI press optimized to run labelstock paper and film packaging materials, and to bridge the gap between narrow and wide web printing for products suchas in-mold andwraparound labels, shrink sleeves,retort stand-up pouches and sachets, as well as paper sacks, cups and plates.

Available in 620 mm (24 inches) and 820 mm (32 inches) widths in up to eight colors, the Optima is capable of speeds up to 300metres aminute (984 ft/min), and features unwind and rewind systems that are located outside the printing unit modules.This variable design allows the option of choosinganyunwindandrewindconfiguration and in-line upstream or downstream printing and converting units such as cold seal or slitting.

An Optima equipped with eight printing units will be shown running live job demonstrations throughout the show. It will feature fast web change over for reverse printing, intelligent impression adjustment to reduce start-up waste and Soma’s new, award-winning print cartridge system for spot colors, which offers printers a means of significantly reducing ink costs on printing jobs where expensive colors, special effects and metallic ink formulations are required.

Sun Chemical Stand 5E45

SunChemicalwill presentits latestinnovations andnewproductlaunches forthe label, narrow web and packaging market at Stand 5E45 at Labelexpo 2015. On display forthe firsttimewill be a new,fully compliantSolarFlex UVFlexo opaquewhite ink for food packaging applications. Also making an introduction will be Polare, a new innovative, versatile and cost-effective ink dispenser range designed to optimize the dispensing of lower volume spot inks.

SunChemical’s digital inkjet division,SunJet, will be highlighting its latest capabilities and expertise in UV curing inks which provide optimum image quality and reliability on a wide range of substrates. Sun Chemical will be displaying its wide range of anti-counterfeiting solutions, including its array of covert and overt inks, SunShift, SunGuard and SunLock, offering brand owners and label producers enhanced product security.

The company will highlight the SunColorBox, its set of applications and services to implement a digitally color managed workflow. SunChemical will also present a wide range of special effect inks and coatings for label applications, including its portfolio of compliant UV flexo inks. Moreover, at Labelexpo there will be SunLase, Sun Chemical’s laser marking coating solution that enables the addition of information to both secondary and primary packaging for practical supply chain purposes or as a late stage pack differentiator.