MGI Digital Technologies, a company based in France, has enjoyed close working relations with Konica Minolta for years. Vijay Kamath, product manager – IP PP & IP marketing, Konica Minolta India, spoke to Packaging South Asia on his company’s association with MGI and its inkjet technology offering, which is now available in India. Konica Minolta, which owns over 40% stake in MGI, has been supplying inkjet heads to the latter for many years now. Their long association has allowed the companies to have a deeper understanding of each other, thus strengthening their relations further.

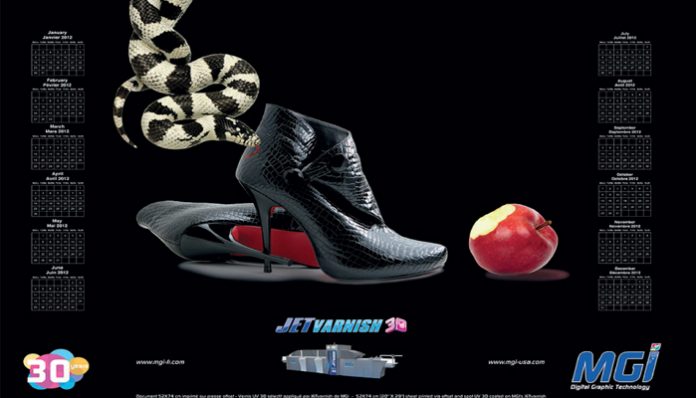

MGI, which is represented in India by Konica Minolta, is a well known name in inkjet technology. The company has recently come up with a premium solution for folding cartons and labels called JETvarnish 3D digital print decoration process. The solution will enable users to achieve a premium branded look for their folding cartons and labels without the time, cost and expenses of using traditional dies, screens or plates. MGI has simplified the production decoration process for manufacturers, printers and converters as its JETvarnish 3D solution helps increase the speed and ability of brands to bring new products into the market at a lower cost. This innovative software offers rapid prototyping for new product launches and full high-volume production management.

The software helps users achieve 2D, 3D and variable foil embossing on cartons and labels on a single line. Printers, converters and finishers can produce special effects with variable data personalization and customized short-runs faster by adopting this technology. The solution is suitable for brand owners looking for multi-sensory packaging to attract consumers at the point of sale. The industry leading JETvarnish 3D takes digital spot UV coating to an entirely new level with increased throughput for flat spot UV jobs and excellent 3D raised effects. It allows for fast start-up without plates, screens or waste, producing anything from one to several thousand sheets per hour easily. On the same document, the JETvarnish 3D can alter the coating thickness from 3 microns to 200 microns, depending on the user’s defined areas.

The JETvarnish 3D can help convert regular printed jobs into high margin spot UV jobs with extended formats going up to 20 x 42 inches and weighing up to 600 gsm. Users can also take a few sheets from a job and spot UV coat it, thereby creating a sellable proof for their customers who will get to see the potential and additional visibility and impact of these jobs. MGI’s inkjet technology offers a higher level of quality and consistency. The precise Piezo (drop-on-demand) print-heads allow for lines as small as 0.5 mm or as wide as the sheet (max. width 20 inches). MGI’s patented coating formula ensures consumers can also switch from one job to another with no equipment cleaning required.