Monarch Graphics, once an associate partner of Jain Transfer Products that started in 2006 is another relatively newcomerin the label industry. About a year and a half ago, Monarch Graphics became totally independent — managed by Pavail Jain and his son Bhrigav Jain. While the company started with a Heidelberg single color offset press and a 2-color screen printing machine, in 2011, Monarch bought anOrthotec 6-colorfully servo-drivenletterpress to focus on the label manufacturing segment, on which the company has been relying completely so far. Now, the company has decided to go in for a new 9-color ECS 340 label press from Gallus with an in-line rotary screen as an option.

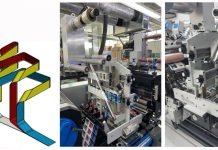

The Gallus ECS340 is a cost-efficient, high-quality commodity label production press says Bhrigav Jain. Exceptionally quiet and stable with minimal waste and set-up times, the Gallus ECS340hasalreadyestablishedaneweraofextremelycost-efficient commodity label printing. When developing this press, Gallus focussed on the essentialfeatures, honing the configuration to maximize print quality while minimizing costs.

The machine’s extremely short web path of just 1.1metre between printing units cuts waste significantly. Due to its granite core, the press has a particularly long service life and is quieter than any other machine in this class. The self-explanatory operation of the Gallus ECS340 with touch-screen technology delivers quicker results. For rapid design and color changes, the press makes use of both print cylinder sleeves and anilox sleeves, along with a chambered doctor blade system. The press is fully servo-driven, allowing register pre-setting.

Bhrigav Jain admits that this new label press is going to be very expensive and is quite an ambitious project for the company. The pressroom at his facility is going through some

modifications as well and Jain tells us that he wants to maintain a temperature of 22°C at all times inside the facility, not only for the long-term efficiency of the machines but also to

keep the workers as fresh and spirited as possible. Jain tells us, “I am willing to incur huge expenses in making my facility a much more hospitable place to work than some other companies and I want my employees to feel the efforts put in by us which should help them in resisting poaching from other companies.”

Young and enthusiastic, Bhrigav Jain believes that the industry is sorely lacking in skilled manpower. The tendency of print engineers to not opt for positions such as an operator or

technician due to a perceived lower social image is hurting the industry he feels. If the industry continues in not being able to attract the right talent, it will be a major loss in the long-term and the industry needs to find away of making it at tractive for fresh talent emerging from colleges, Jain said.

Achievinganaveragegrowthof 30% onanyearto yearbasis, Jaintellsus the company has been on a learning curve since inception but with the addition of the new press which will take another month to be installed and commissioned, Monarch Graphics would be able to take up new jobs which could not be executed in his previous 6-color machine.Cold foiling jobs is one such novelty for him which could not be done previously butfrom now on he can take up even the most challenging jobs. He says, “After this press is installed, I will be spending at least the next three months in-housewith the newpress so as to learn allthe intricacies ofthemachine. This will help me in pushing the boundary when we start doing jobs on this press at a serious level.”

So far business has been good for Monarch Graphics, Jain adds. “Business is good because of my father. He has been in this industry for the last 32 years. I have to work hard to be recognized.” But, he also believes that dedication coupled with positivity and his father’s experiencewillholdhimingoodsteadinthelongrun.Sincethe company is not too big, he believes the flexibility which he can offer to the clients will be difficult to manage by other big label printing companies. He says, “Skilled man power and training are two of the most essential ingredients of any successful industry and ours is no exception. People have to realize that instead of this poaching mentality if all companies impart quality training to its manpower and create better working environments for them, the entire industry stands to be benefited.”