Bengaluru-based Wintek Flexo Prints is a part of Signode India and one of the leading printing and converting firms for the supply of self-adhesive labels to various segments such as FMCG, pharmaceuticals and industrial sectors. By mid-June 2015, the company will install a 9-color Gallus EM 280 upgraded with online screen printing, and hot and cold foil stamping at its Rudrapur plant.

Wintek is a leading user ofGallus label presses in the country. Gururaj Ballarwad, managing partner, Wintek, said, “In Bengaluru, we recently installed onemoreGallus,theECS340. For Rudrapur, other brands were also considered but with Gallus, there is hardly any need to train our production staff. Moreover, jobs can be transferred from Bengaluru to the Rudrapur plant as similar plates are used in both units.”

“Due to the exemption of excise duty and to offer our services in the northern region we invested in the Rudrapur plant. Because of the kind of work we are expecting there, we chose theGallusEM280 which is economical and with auto-registration produces fine-quality label printing on paper, film and paper laminates. It is a good option for long-runs, easy to operate and to switch between flexographic, screen, hot foil embossing and cold foil printing units. The press consists of a water cooling system, is noiseless and has a long service lifewithnominalwastage.WiththeGallusEM280we can increase production capacity by 20% and can expect a commensurate increase in revenue,” said Ballarwad.

Elaborating his reasons for choosing Gallus, Ballarwad stated, “When we made the first purchase, Gallus was represented in India by Heidelberg with its after-sales service. Due to availability of local support from Heidelberg, we opted for Gallus machines. Other brands were available but lacked proper after-sales support and so we stuck with Gallus. Moreover, Gallus has been a trusted brand since many years in the printing industry.”

Currently Wintek has a single press line in Rudrapur and wants to make it a hub forthe northern region. The Rudrapur plant includes production and quality control systems but does not have a prepress unit. Plates to the Rudrapur plant will be supplied by the unit in Bengaluru which has a complete in-house Esko packaging design and prepress system including a digital flexo imager. “With the help of the new plant, we can easily offer services to our customers at a lower cost of input material and transport,” says Ballarwad.

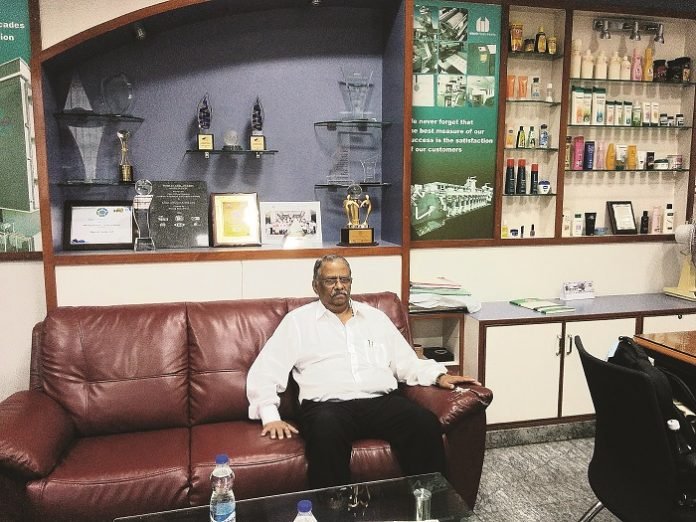

Recently Wintek received an award from the Asian Flexographic Technical Association at Bangkok for quality in printing. Wintek is also an environmentally conscious company that has tackled difficult to recycle label production waste. The waste generated at Wintek is converted into edge boards and other recycled industrial products. Speaking about flexography and the label industry Ballarwad says, “It is witnessing a growth of around 15 to 18% every year. With the advent of new technologies, flexo printing is gaining popularity with enhanced print quality, modular designs and less change over time.”